We understand the challenges of various industries, and manufacture reliable quality products through top-notch equipment and professional production technology, so that customers' ideas can be quickly realized.

about Jiangsu Jend Tube Co.,Ltd.

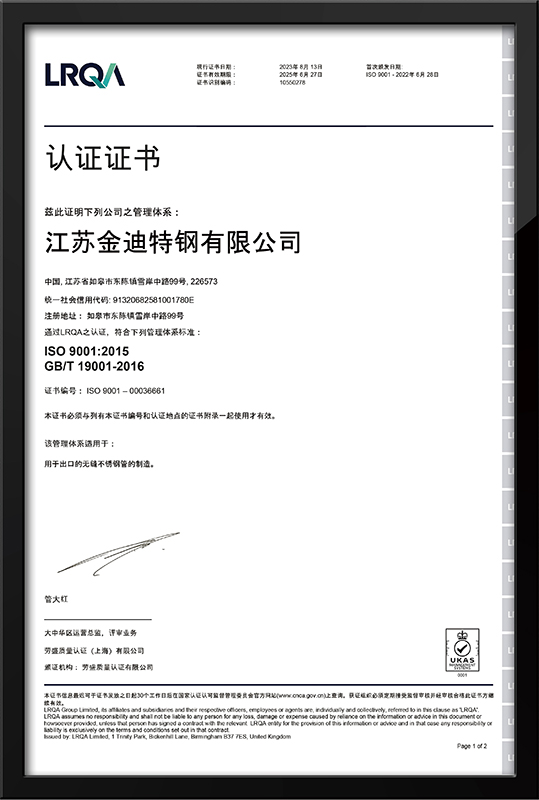

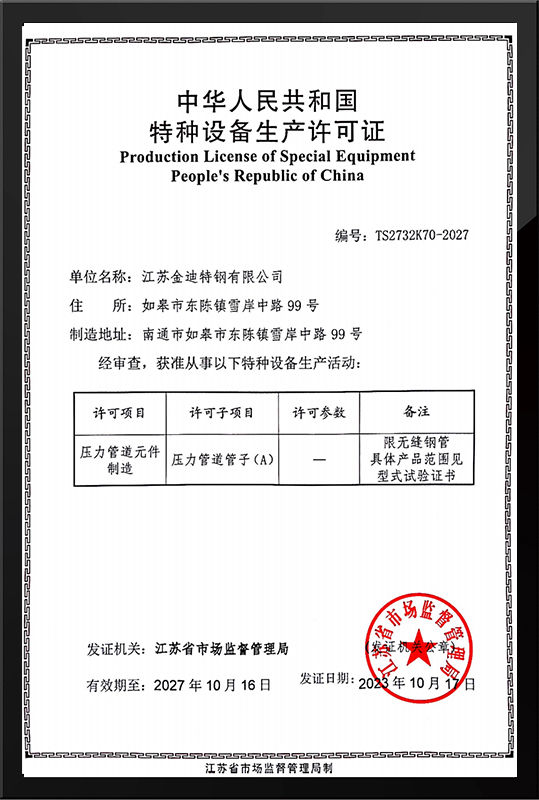

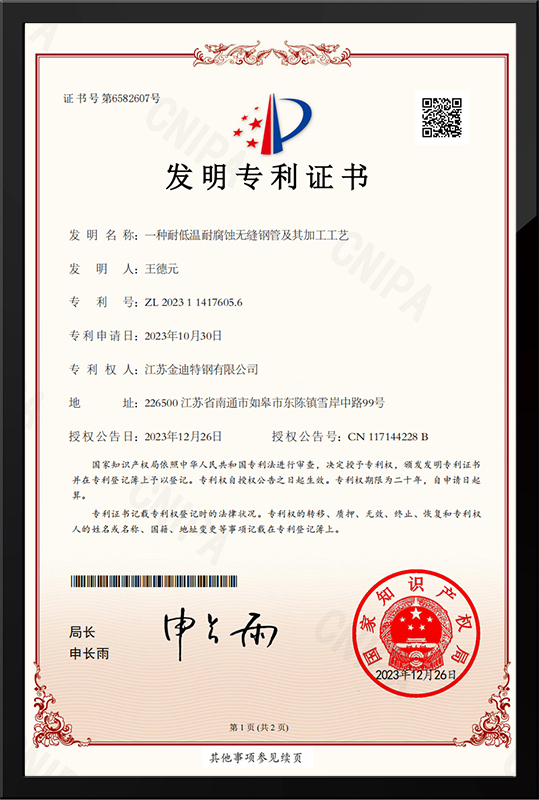

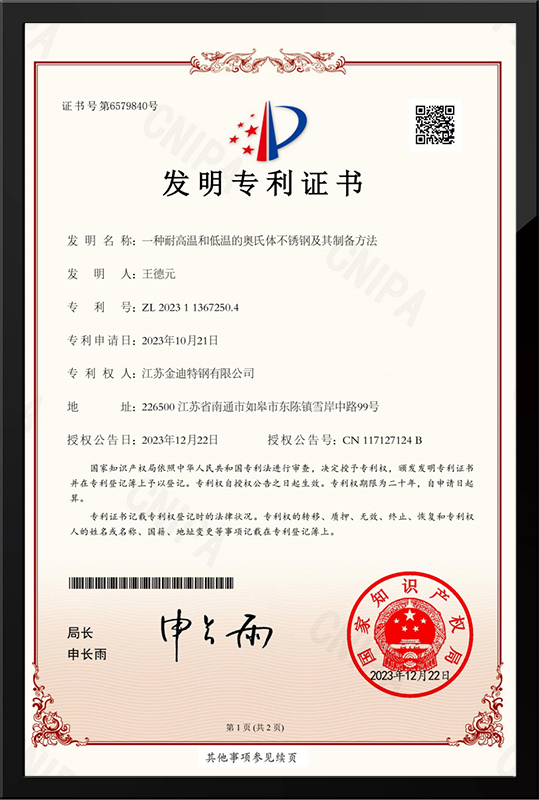

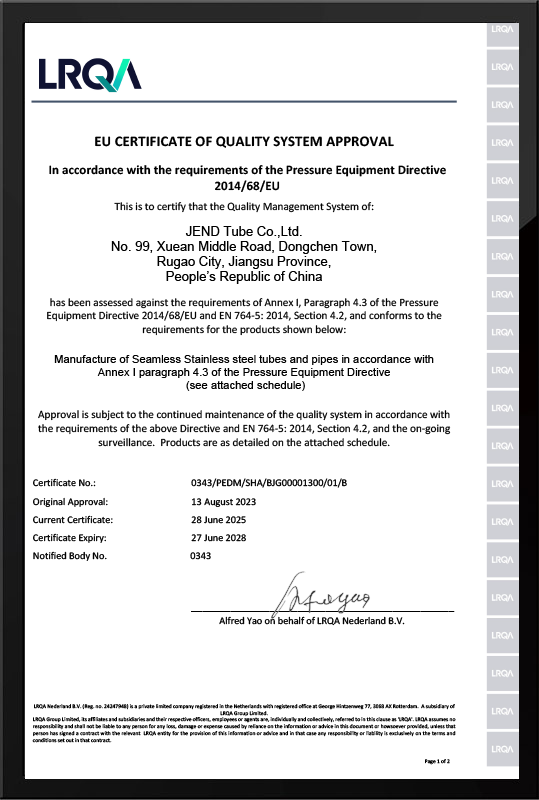

As China Duplex Steel Tube Manufacturers and Seamless Duplex Steel Tube Suppliers, Established in 2011 and is a manufacturing enterprise with a complete manufacturing cycle from raw material selection to finished product delivery. The company currently has more than 100 employees, covers an area of 30015 square meters, and has a registered captial of 48 million yuan, annual production capacity of 3800 tons. The company has passed ISO9001:2015 quality certification, domestic pressure vessel TS certification, and foreign pressure vessel PED certification. With rich experience and mature technology, we have been expanding our market internationally. At present, our products are exported to more than 50 countries and regions including Europe, America, Southeast Asia, and the Middle East. The company adheres to different production norms and standards such as the American standard (ASTM), the European standard (EN), the German standard (DIN), the Japanese standard (JIS), the Russian standard (GOST), and the Chinese standard (GB). Our company specializes in and customizes various specifications of Martensite TP410 (0Cr13, 1Cr13), Ferrite TP405 (1Cr13Al), TP430 (1Cr17), TP444 (0Cr18Mo2), TP439, TP409 (0Cr11Ti), It is also proficient in manufacturing Austenitic seamless stainless steel pipes of series such as TP304(L/H),TP316(L/H/Ti),TP310S,TP317,TP321(H) and TP347(H). Duplex such as S31803、S2205、S32750、S32304, and Nickel-based alloys Monel400, Monel600, Monel800, GH3030, 904L,Inconel 625,etc. The company mainly produces seamless steel pipes with the following specifications: outer diameter: 3.18mm to 406.4mm, wall thickness: 0.3mm to 20mm, and the longest length is 25000mm. Additionally, it can customize seamless steel pipes with special materials and specifications according to customer requirements. The company attaches great importance to scientific innovation. The staff of the company vigorously develop technological research and development. Jiangsu Jend Tube Co.,Ltd.will continuously accumulate professional knowledge and capabilities, striving to become a leader in the domestic market and even the world market. Strive to be the most reassurring pipe manufacturing enterprise for customers.

news

centerAuthentic reliable quality naturally stands out and fears no comparison.

All news-

Why is Austenitic Stainless Steel Tube the Best Choice for High-Corrosion Environments

Unveiling Stainless Steel: From Alloy Definition to the Core of Austenite Stainless steel is not a single material but a vast family of iron-based alloys. The c

-

Why is the Austenitic Stainless Steel Tube the Top Choice for Industrial Piping

In the realm of modern industrial manufacturing and fluid transport, the selection of stainless steel tubing directly dictates the safety and longevity of the e

-

Which Stainless Steel Tube Type is Best for Your Project? (304 vs 316 vs 2205)

Austenitic Stainless Steel Tubing Austenitic stainless steel tubing is the most widely used category of Stainless Steel Tube in both industrial and civil fields

-

Why Does My Stainless Steel Tube Still Rust? The Truth About Ferritic Grades

1. Corrosion Resistance Principles of Ferritic Stainless Steel The corrosion resistance of ferritic stainless steel is primarily due to its high Chromium conten

INDUSTRY KNOWLEDGE EXTENSION

Structural advantages and manufacturing practices of duplex steel tubes

What is duplex steel tube?

duplex steel tube refers to steel that contains both austenite and ferrite in the metal structure, and the two phases generally account for nearly 50% each. This structure enables duplex steel to have both the rust-resistant and corrosion-resistant characteristics of austenite and the strength and chloride stress corrosion resistance of ferrite, so it has certain advantages in some special application environments.

The duplex steel series produced by Jiangsu Jend Tube Co., Ltd. includes multiple models such as S31803, S2205, S32750, S32304, covering a variety of options from standard to super duplex steel.

Structural advantages of duplex steel tubes

High strength: Compared with conventional austenitic stainless steel, the tensile strength of duplex steel can usually reach about 1.5 times that of conventional austenitic stainless steel, which means that under the same strength requirements, it can be designed to be thinner and lighter, which helps to reduce the overall weight of the equipment.

Stress corrosion resistance: Ferrite structure can effectively resist stress corrosion cracking caused by chloride ions, so duplex steel is more stable in chlorine-containing environments, such as seawater, salt spray and other working conditions.

Local corrosion resistance: including pitting and crevice corrosion. Duplex steel is often used to make equipment such as heat exchangers, condensers, chemical tubelines, etc. that need to be in long-term contact with corrosive media.

Reasonable weldability: Although the welding process of duplex steel is more complicated than that of austenitic steels such as 304/316, stable performance welded joints can be obtained by reasonably controlling welding parameters.

Manufacturing Capabilities and Practices of Jiangsu Jend Tube Co., Ltd.

As an enterprise with full-process production capabilities from material selection to finished product delivery, Jiangsu Jend Tube Co., Ltd. has the following advantages in the manufacturing of duplex steel tubes:

Multi-specification coverage: The company can produce seamless duplex steel tubes with an outer diameter of 3.18mm to 406.4mm, a wall thickness of 0.3mm to 20mm, and a length of up to 25,000mm, which can meet the special design needs of customers in multiple industries.

Strict composition control: Use analyzers to accurately detect key alloying elements (such as chromium, molybdenum, nitrogen, etc.) to ensure that the proportion of steel structure is reasonable to achieve the expected strength and corrosion resistance.

Heat treatment control in place: Duplex steel has high requirements for heat treatment. The company adopts a precise temperature control solution treatment process to keep the two-phase structure of the steel stable during heating and cooling.

Support customized services: According to customer drawings, use environment and project standards, customized services of non-standard sizes and specific materials can be provided to improve engineering adaptability.

Industry development trends and changes in customer needs

In recent years, as various industries pay more attention to the service life, safety and environmental performance of materials, the market demand for duplex stainless steel has continued to grow. From the early small-batch high-end applications, it has gradually expanded to one of the standard configuration materials for large-scale engineering equipment.

Some development trends worth paying attention to include:

Replacing traditional austenitic materials: In some environments with high corrosion resistance requirements, customers have begun to use duplex steel as an alternative to traditional austenitic steels such as 316L.

Adapting to global standards: More and more customer projects require compliance with international standards such as ASME, ASTM, and EN, which promotes manufacturing companies to strengthen quality control and standard certification.

Green and low-carbon manufacturing: Environmental regulations are becoming increasingly stringent, driving the manufacturing process to transform towards energy conservation, emission reduction, and sustainability. Jiangsu Jend Tube Co., Ltd. also continues to optimize energy efficiency and waste treatment.

Future Outlook

As more industries pay attention to equipment life cost and reliability, duplex steel tubes will play a greater role in scenarios such as tubeline systems, pressure vessels, and marine equipment. Jiangsu Jend Tube Co., Ltd. will also continue to improve its technology level, strengthen international cooperation, and continuously expand product application areas and service models.

Through steady manufacturing strategies and customer-oriented product design, the company will form stronger technical support capabilities in the duplex stainless steel market.

From manufacturing to service: technology and practice in the duplex steel tube industry chain

In modern industrial manufacturing, materials must not only meet specific performance requirements, but also be highly matched in processing, supply and service. As an engineering material that combines mechanical properties with corrosion resistance, duplex steel tubes have long been able to win the market not just by relying on the "material" itself. Its production process, processing accuracy, delivery flexibility and customer customization capabilities are becoming the core factors for companies to compete in the global market.

Key control nodes in the manufacturing process

In the production process of Jiangsu Jend Tube Co., Ltd., the manufacturing of duplex steel tubes is divided into multiple stages, from billet procurement, heat treatment, cold processing, testing to finished product packaging, and each step has a quality monitoring node.

For example, in the heat treatment link, the company uses a continuous temperature control system to ensure the stability of the austenite and ferrite phase ratio, thereby avoiding local structural segregation. In the cold processing stage, such as cold drawing and cold rolling, the deformation amount and intermediate annealing frequency must be strictly controlled to prevent the material from hardening too fast or the structure from deforming, affecting the subsequent service life.

Before the finished product leaves the factory, it must pass processes such as water pressure testing, air tightness testing and metallographic analysis to verify the consistency of the welding interface and the matrix structure.

Customization is a new track for corporate competition

The traditional mass production idea can no longer meet the needs of some engineering projects. Jiangsu Jend Tube Co., Ltd. provides a more flexible solution in this regard: the wall thickness, outer diameter and even alloy composition ratio of the tube can be adjusted according to the technical drawings or usage scenarios provided by the customer.

For example, some marine equipment manufacturers will specifically require an increase in the nitrogen content of steel tubes to enhance the ability to resist stress corrosion; while in the papermaking industry, some customers will require fine-tuning of the chromium-nickel ratio based on S31803 to adapt to specific chemical media.

This "formula-level" customization not only places higher requirements on raw material procurement, but also challenges the adjustability of production control. The laboratory team of Jiangsu Jend Tube Co., Ltd. can complete composition adjustment, small-batch trial production and simulated service testing within 3 days, so that customers do not have to wait for a long development cycle.

Efficiency management of logistics and delivery

In international business, the transportation process of tubes has a direct impact on product quality. Jiangsu Jend Tube Co., Ltd. focuses on three measures in packaging and logistics: moisture-proof, anti-collision and anti-bending.

For example, for duplex steel tubes longer than 12 meters, the company uses a multi-point support frame packaging method, combined with a special closed container for sea transportation, to reduce transportation losses. In addition, in view of the sensitivity of customers in the Middle East and Southeast Asia to delivery dates, the company has a basic inventory of conventional models all year round, so as to achieve fast delivery in 2 to 4 weeks, which is far lower than the industry average.

Customer service has shifted from "after-sales" to "full-process collaboration"

As material engineering projects develop towards systematization and customization, Jiangsu Jend Tube Co., Ltd. has gradually put "after-sales service" in the front and developed it into a full-process technical collaboration mechanism. Customers can connect with the technical team at the beginning of the design, and the technical staff will provide material selection suggestions, structural stress analysis, and subsequent welding matching suggestions.

This method is particularly popular among large equipment manufacturers. For example, in a project for a European and American pressure vessel customer, technical engineers from Jiangsu Jend Tube Co., Ltd. participated in the formulation of material specifications and procurement plan design from the beginning of the project, which ultimately shortened the total development cycle by more than 20%.

Future Trends: Green Manufacturing and International Certification

Facing increasingly stringent environmental protection policies and market access barriers, Jiangsu Jend Tube Co., Ltd. is gradually promoting green manufacturing transformation. In the process of producing duplex steel tubes, the company has invested in waste gas recovery and treatment systems and adopted low-energy heat treatment technology to reduce unit energy consumption.

The company has currently obtained a number of international certifications including ISO 9001, PED, AD2000, and actively participated in domestic and international standardization projects. These measures will help its products enter the global high-demand market more smoothly.

한국어

한국어 русский

русский عربى

عربى