We understand the challenges of various industries, and manufacture reliable quality products through top-notch equipment and professional production technology, so that customers' ideas can be quickly realized.

about Jiangsu Jend Tube Co.,Ltd.

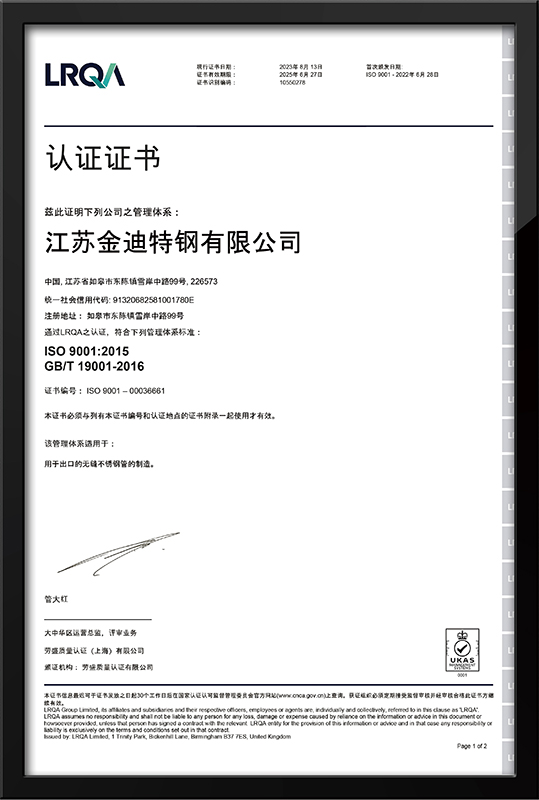

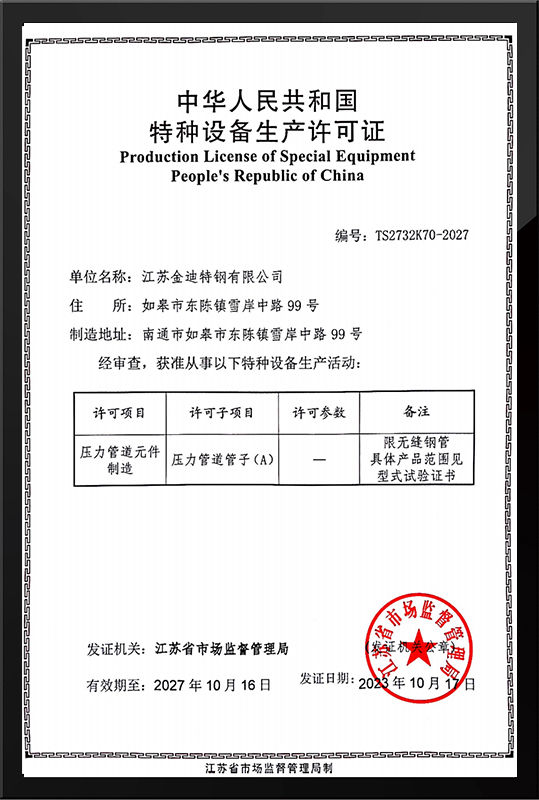

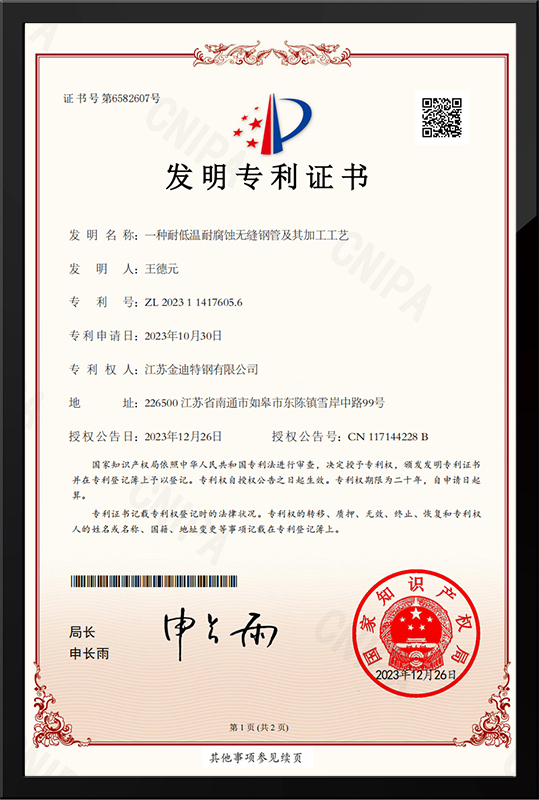

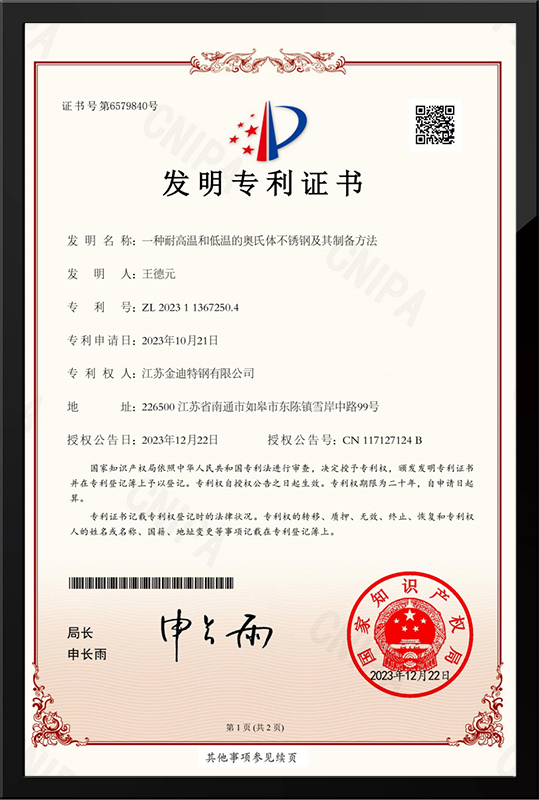

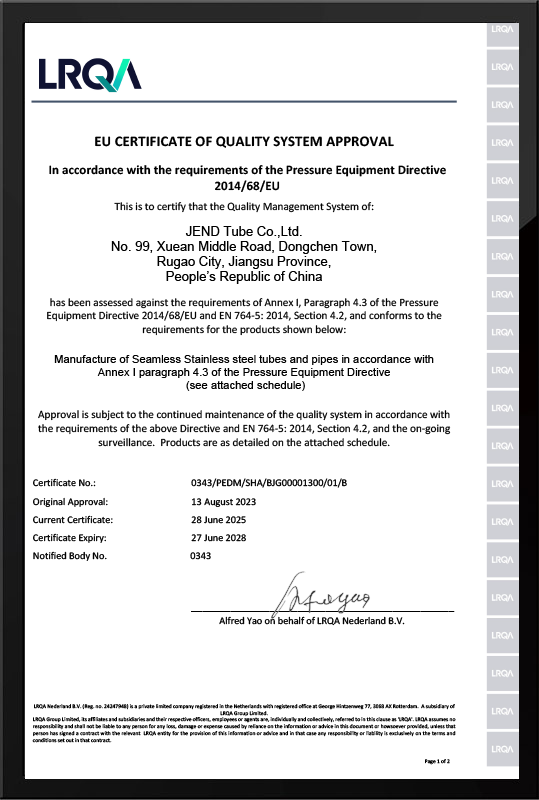

As China Ferritic Stainless Steel Tube Manufacturers and Seamless Ferritic Stainless Steel Tube Suppliers, Established in 2011 and is a manufacturing enterprise with a complete manufacturing cycle from raw material selection to finished product delivery. The company currently has more than 100 employees, covers an area of 30015 square meters, and has a registered captial of 48 million yuan, annual production capacity of 3800 tons. The company has passed ISO9001:2015 quality certification, domestic pressure vessel TS certification, and foreign pressure vessel PED certification. With rich experience and mature technology, we have been expanding our market internationally. At present, our products are exported to more than 50 countries and regions including Europe, America, Southeast Asia, and the Middle East. The company adheres to different production norms and standards such as the American standard (ASTM), the European standard (EN), the German standard (DIN), the Japanese standard (JIS), the Russian standard (GOST), and the Chinese standard (GB). Our company specializes in and customizes various specifications of Martensite TP410 (0Cr13, 1Cr13), Ferrite TP405 (1Cr13Al), TP430 (1Cr17), TP444 (0Cr18Mo2), TP439, TP409 (0Cr11Ti), It is also proficient in manufacturing Austenitic seamless stainless steel pipes of series such as TP304(L/H),TP316(L/H/Ti),TP310S,TP317,TP321(H) and TP347(H). Duplex such as S31803、S2205、S32750、S32304, and Nickel-based alloys Monel400, Monel600, Monel800, GH3030, 904L,Inconel 625,etc. The company mainly produces seamless steel pipes with the following specifications: outer diameter: 3.18mm to 406.4mm, wall thickness: 0.3mm to 20mm, and the longest length is 25000mm. Additionally, it can customize seamless steel pipes with special materials and specifications according to customer requirements. The company attaches great importance to scientific innovation. The staff of the company vigorously develop technological research and development. Jiangsu Jend Tube Co.,Ltd.will continuously accumulate professional knowledge and capabilities, striving to become a leader in the domestic market and even the world market. Strive to be the most reassurring pipe manufacturing enterprise for customers.

news

centerAuthentic reliable quality naturally stands out and fears no comparison.

All news-

Why is Austenitic Stainless Steel Tube the Best Choice for High-Corrosion Environments

Unveiling Stainless Steel: From Alloy Definition to the Core of Austenite Stainless steel is not a single material but a vast family of iron-based alloys. The c

-

Why is the Austenitic Stainless Steel Tube the Top Choice for Industrial Piping

In the realm of modern industrial manufacturing and fluid transport, the selection of stainless steel tubing directly dictates the safety and longevity of the e

-

Which Stainless Steel Tube Type is Best for Your Project? (304 vs 316 vs 2205)

Austenitic Stainless Steel Tubing Austenitic stainless steel tubing is the most widely used category of Stainless Steel Tube in both industrial and civil fields

-

Why Does My Stainless Steel Tube Still Rust? The Truth About Ferritic Grades

1. Corrosion Resistance Principles of Ferritic Stainless Steel The corrosion resistance of ferritic stainless steel is primarily due to its high Chromium conten

INDUSTRY KNOWLEDGE EXTENSION

Basic knowledge and manufacturing status of ferritic stainless steel tubes

Jiangsu Jend Tube Co., Ltd. was established in 2011. It is a production-oriented enterprise integrating raw material procurement, production and processing to finished product delivery. With many years of industry experience and mature technology, the company's products are exported to more than 50 countries and regions including Europe, America, Southeast Asia, and the Middle East. Its production line covers a variety of stainless steel tubes, including ferritic stainless steel tubes. This article will introduce the basic concepts, manufacturing processes, material properties and market applications of ferritic stainless steel tubes to help readers better understand this important steel category.

What is ferritic stainless steel tube?

Ferritic stainless steel tube is a stainless steel tube with ferrite as the main microstructure. Compared with austenitic stainless steel tubes and martensitic stainless steel tubes, ferritic stainless steel tubes have a lower carbon content and a moderate chromium content, generally around 10.5% to 30%. The organization of ferritic stainless steel is a body-centered cubic structure, which determines that it has certain advantages in corrosion resistance, oxidation resistance and stress corrosion cracking resistance.

Jiangsu Jend Tube Co., Ltd. mainly produces ferrite series including TP405 (1Cr13Al), TP430 (1Cr17), TP444 (0Cr18Mo2), TP439, TP409 (0Cr11Ti), etc. These steels are suitable for different industrial fields to meet the diverse needs of customers.

Manufacturing process introduction

The production process of ferritic stainless steel tubes usually includes smelting, casting, hot rolling, cold working, heat treatment and surface treatment. Jiangsu Jend Tube Co., Ltd. implements strict quality management in each link.

Melting and casting: using advanced electric furnace smelting technology to ensure uniform and pure molten steel composition.

Hot rolling and cold rolling: by controlling the rolling temperature and speed, adjust the size and mechanical properties of the steel tube to meet the design requirements.

Heat treatment: for different uses, select appropriate solution treatment and annealing processes to ensure the stability of the internal structure of the material.

Surface treatment: In order to improve the corrosion resistance and aesthetics of the tube, pickling, passivation and other processes are usually carried out.

These processes ensure that ferritic stainless steel tubes have stable physical and chemical properties and can adapt to various complex working conditions.

Performance characteristics of ferritic stainless steel tubes

Due to their organizational structure, ferritic stainless steel tubes show the following characteristics in practical applications:

Stress corrosion cracking resistance: Ferritic steel has good resistance to stress corrosion cracking and is suitable for use in certain corrosive environments.

High temperature resistance: Some ferritic steel grades, such as TP444, contain higher chromium and molybdenum elements and can withstand oxidizing environments at higher temperatures.

Thermal conductivity and thermal expansion coefficient: Ferritic steel has a lower thermal expansion coefficient and better thermal conductivity, which is an advantage for some heat exchange equipment.

Plasticity and toughness: Although the plasticity and toughness of ferritic stainless steel are usually not as good as those of austenitic steel, it can still maintain relatively stable mechanical properties in the medium temperature range.

These properties make ferritic stainless steel tubes competitive in the industrial field.

Application fields and market demand

Ferritic stainless steel tubes are widely used in industries such as chemical industry, petroleum, boiler manufacturing, automobile industry, architectural decoration and home appliance manufacturing. For example, TP405 steel is often used in automobile exhaust systems, while TP444 is suitable for high-temperature flue gas tubes and heat exchangers. Jiangsu Jend Tube Co., Ltd. provides diversified specifications and material options to meet the needs of different customers and meet the application of multiple industries and scenarios.

With the increasing requirements of industrial equipment for material performance and durability, the market demand for ferritic stainless steel tubes has gradually increased. Especially in the context of increasingly prominent demand for high temperature resistance and corrosion resistance, the application prospects of ferritic stainless steel tubes continue to be promising.

Technical advantages of Jiangsu Jend Tube Co., Ltd.

As a professional seamless steel tube manufacturer, Jiangsu Jend Tube Co., Ltd. not only has complete production equipment, but also pays attention to R&D investment. The company continues to introduce advanced testing equipment and production technology to improve the overall quality and stability of its products. Through strict process control and quality management, it ensures that each batch of ferritic stainless steel tubes shipped meets customer standards. The company can customize ferritic steel tubes of different sizes and materials according to the personalized needs of customers, and provide one-stop services from design consultation to product delivery.

Ferritic stainless steel tube: a new perspective on production process and industry development

Since its establishment in 2011, Jiangsu Jend Tube Co., Ltd. has relied on a complete production system and rich technical accumulation to manufacture and innovate a series of products such as ferritic stainless steel tubes. As an enterprise in the industry with full-process capabilities from raw material procurement to finished product delivery, the company continues to introduce advanced equipment and optimize processes to actively respond to multiple challenges in the market and technology. This article will focus on the production process, quality management, industry trends and future development of ferritic stainless steel tubes, providing an analysis from a different perspective from common performance and application.

Production process innovation of ferritic stainless steel tubes

The production process of ferritic stainless steel tubes covers multiple links such as material selection, smelting, rolling, cold processing and heat treatment. Jiangsu Jend Tube Co., Ltd. continues to promote technological improvements based on traditional processes:

Material uniformity control

Use high-precision chemical composition analysis instruments to ensure the stability of alloy element content, reduce element segregation, and improve the overall quality uniformity of steel tubes.

Efficient heat treatment process

By optimizing the heat treatment temperature and time, grain refinement and effective release of residual stress can be achieved, and the processing performance and subsequent service life of steel tubes can be improved.

Application of automated production lines

Introducing automated equipment to achieve real-time online control of tube size measurement, wall thickness monitoring and surface defect detection, reduce human errors and ensure stable production.

Green manufacturing concept

The company pays attention to environmental protection and promotes energy-saving and emission reduction measures, such as high-efficiency furnace body transformation and waste gas recovery and treatment, to reduce the impact of production on the environment.

These process innovations not only improve the manufacturing efficiency of ferritic stainless steel tubes, but also provide a strong guarantee for the quality stability of products.

Construction of quality control system

The stability of ferritic stainless steel tube product quality is an important factor for Jiangsu Jend Tube Co., Ltd. to win the trust of customers. To this end, the company has established a multi-level quality management system:

Raw material entry inspection

Strictly review the qualifications of suppliers, use imported or high-standard billets, and rationalize inspections to ensure that the raw materials meet production requirements.

Process quality monitoring

Quality inspection points are set up in each link from smelting to forming, and non-destructive testing (NDT) technologies such as ultrasonic flaw detection and radiographic testing are used to ensure that there are no internal defects.

Final inspection and packaging standards

After the product is completed, the size, surface state and mechanical properties are systematically tested. After passing the test, protective packaging is used to ensure that it is not damaged during transportation.

Traceability management system

Through the numbering system, the production data of each batch of products can be traced, which is convenient for customers and enterprises to respond to quality issues in a timely manner.

This system ensures that every step of ferritic stainless steel tubes from raw materials to delivery is effectively supervised.

Industry trends and market challenges

With the increasing diversity of industrial application needs, the market environment for ferritic stainless steel tubes is also constantly evolving:

Material diversification needs

The growing demand for special performance steel grades in the industry has prompted companies to develop new ferritic steels with low carbon and high chromium content to adapt to more complex working conditions.

Fine production direction

The market's requirements for tube dimensional accuracy and surface quality have increased, prompting production technology to develop in the direction of fine processing and intelligent control.

Environmental protection and sustainable development pressure

Energy conservation and emission reduction in the manufacturing process have become a topic that companies must face, and green production has become an industry development trend.

Changes in the international trade environment

Global trade policy fluctuations affect the export market, and companies need to enhance supply chain resilience and optimize logistics and inventory management.

Jiangsu Jend Tube Co., Ltd. actively responds to the above challenges and steadily improves its market competitiveness through continuous technology upgrades and strict management.

Future Development Direction

Looking to the future, the ferritic stainless steel tube industry will focus on the following directions:

Intelligent Manufacturing Upgrade

Combined with the Internet of Things and big data technology, promote intelligent monitoring of production processes and predictive maintenance of equipment, and improve production efficiency and quality controllability.

Deepening of Product Customization

Relying on customer needs, develop customized products with multiple specifications and multiple materials to meet the differentiated application needs of special industries.

Strengthening R&D Investment

Increase the research and development of new materials and new processes, such as high temperature resistant and corrosion resistant new ferritic steel, to expand the boundaries of product performance.

Promotion of Green Processes

Deepen the recycling of resources and environmental protection, and actively respond to the national energy conservation and emission reduction policies.

Jiangsu Jend Tube Co., Ltd. plans to rely on its own technical accumulation and market experience, continue to innovate, and maintain steady development in the field of ferritic stainless steel tube manufacturing.

한국어

한국어 русский

русский عربى

عربى