We understand the challenges of various industries, and manufacture reliable quality products through top-notch equipment and professional production technology, so that customers' ideas can be quickly realized.

about Jiangsu Jend Tube Co.,Ltd.

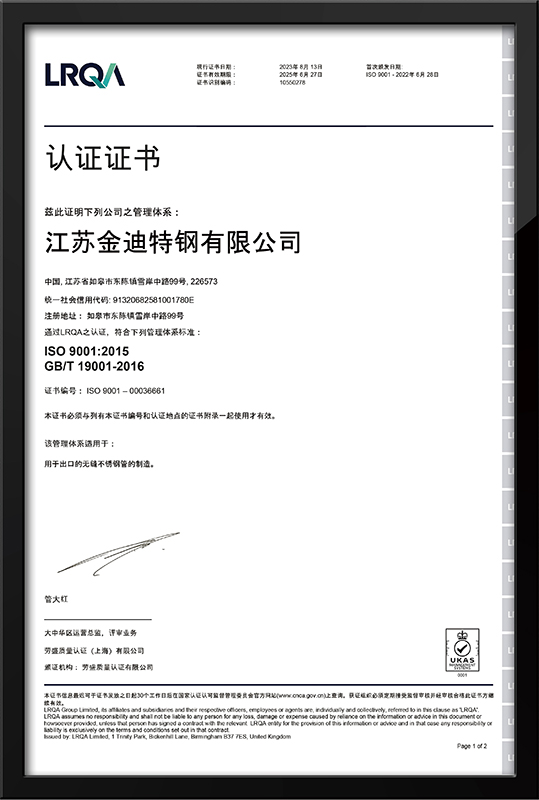

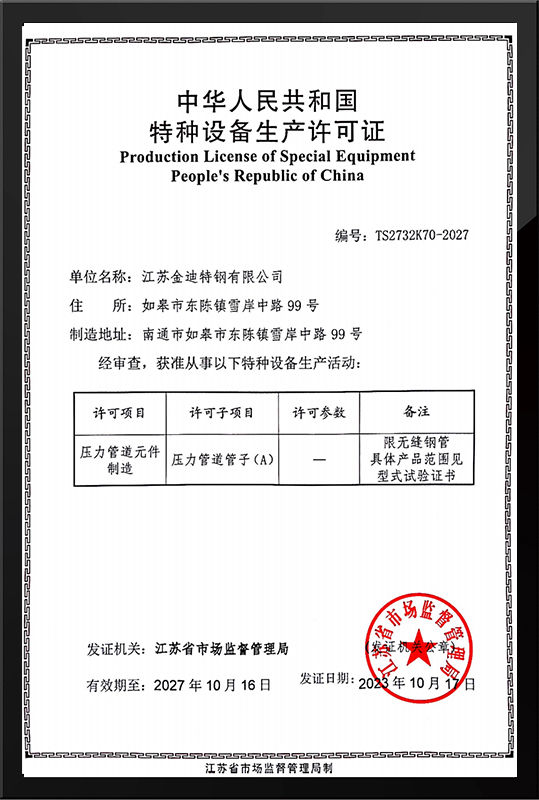

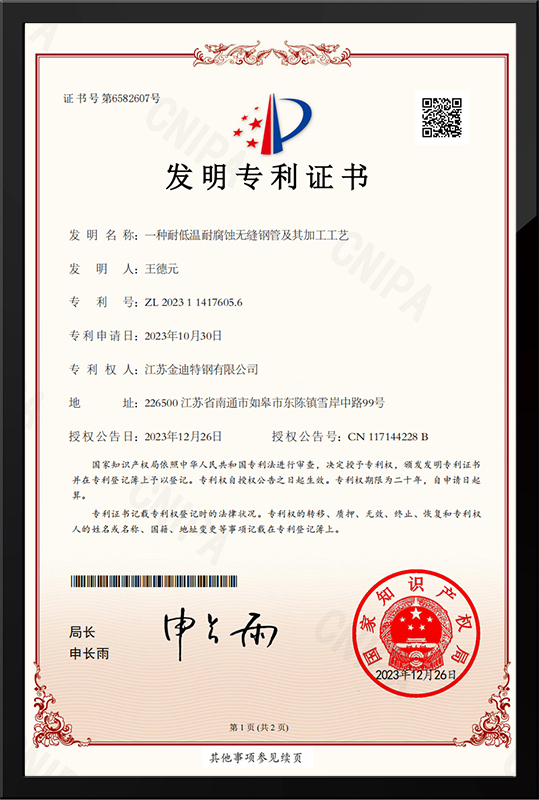

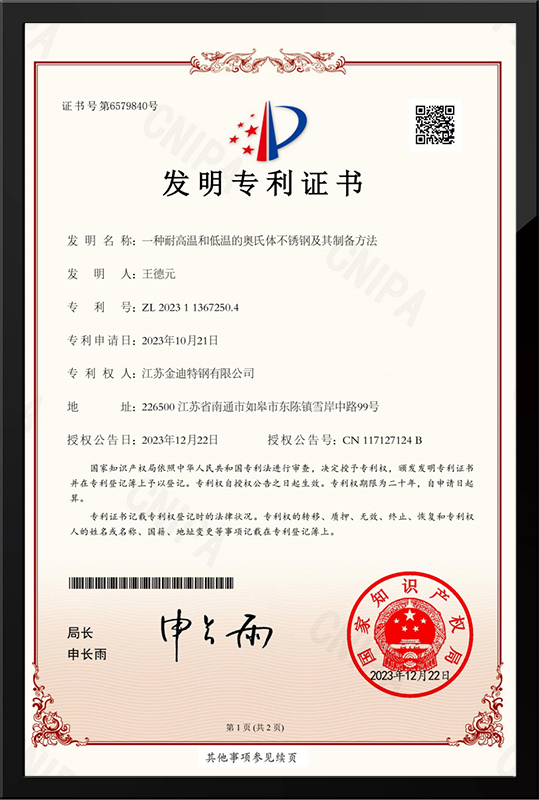

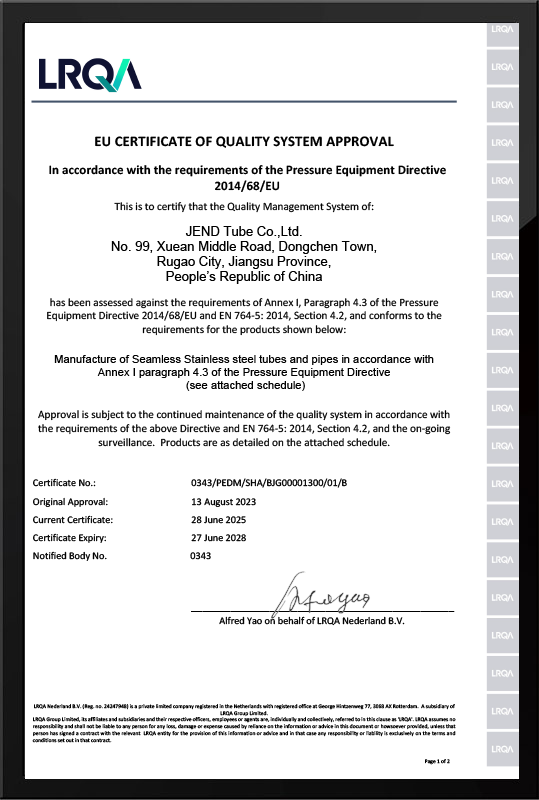

As China Austenitic Stainless Steel Tube Manufacturers and Seamless Austenitic Stainless Steel Tube Suppliers, Established in 2011 and is a manufacturing enterprise with a complete manufacturing cycle from raw material selection to finished product delivery. The company currently has more than 100 employees, covers an area of 30015 square meters, and has a registered captial of 48 million yuan, annual production capacity of 3800 tons. The company has passed ISO9001:2015 quality certification, domestic pressure vessel TS certification, and foreign pressure vessel PED certification. With rich experience and mature technology, we have been expanding our market internationally. At present, our products are exported to more than 50 countries and regions including Europe, America, Southeast Asia, and the Middle East. The company adheres to different production norms and standards such as the American standard (ASTM), the European standard (EN), the German standard (DIN), the Japanese standard (JIS), the Russian standard (GOST), and the Chinese standard (GB). Our company specializes in and customizes various specifications of Martensite TP410 (0Cr13, 1Cr13), Ferrite TP405 (1Cr13Al), TP430 (1Cr17), TP444 (0Cr18Mo2), TP439, TP409 (0Cr11Ti), It is also proficient in manufacturing Austenitic seamless stainless steel pipes of series such as TP304(L/H),TP316(L/H/Ti),TP310S,TP317,TP321(H) and TP347(H). Duplex such as S31803、S2205、S32750、S32304, and Nickel-based alloys Monel400, Monel600, Monel800, GH3030, 904L,Inconel 625,etc. The company mainly produces seamless steel pipes with the following specifications: outer diameter: 3.18mm to 406.4mm, wall thickness: 0.3mm to 20mm, and the longest length is 25000mm. Additionally, it can customize seamless steel pipes with special materials and specifications according to customer requirements. The company attaches great importance to scientific innovation. The staff of the company vigorously develop technological research and development. Jiangsu Jend Tube Co.,Ltd.will continuously accumulate professional knowledge and capabilities, striving to become a leader in the domestic market and even the world market. Strive to be the most reassurring pipe manufacturing enterprise for customers.

news

centerAuthentic reliable quality naturally stands out and fears no comparison.

All news-

Why is Austenitic Stainless Steel Tube the Best Choice for High-Corrosion Environments

Unveiling Stainless Steel: From Alloy Definition to the Core of Austenite Stainless steel is not a single material but a vast family of iron-based alloys. The c

-

Why is the Austenitic Stainless Steel Tube the Top Choice for Industrial Piping

In the realm of modern industrial manufacturing and fluid transport, the selection of stainless steel tubing directly dictates the safety and longevity of the e

-

Which Stainless Steel Tube Type is Best for Your Project? (304 vs 316 vs 2205)

Austenitic Stainless Steel Tubing Austenitic stainless steel tubing is the most widely used category of Stainless Steel Tube in both industrial and civil fields

-

Why Does My Stainless Steel Tube Still Rust? The Truth About Ferritic Grades

1. Corrosion Resistance Principles of Ferritic Stainless Steel The corrosion resistance of ferritic stainless steel is primarily due to its high Chromium conten

INDUSTRY KNOWLEDGE EXTENSION

Performance characteristics and market application paths of austenitic stainless steel tubes

In the modern industrial material system, austenitic stainless steel tubes have become the preferred material in many key fields due to their good corrosion resistance, forming processability and temperature adaptability. Especially in the chemical, energy, food, machinery, medicine and other industries, the functions of tubeline transportation, structural support, corrosion-resistant applications undertaken by austenitic stainless steel tubes are increasingly valued.

As a stainless steel tube manufacturer with a complete production system and an international vision, Jiangsu Jend Tube Co., Ltd. has formed a mature system in the research and development and manufacturing of austenitic stainless steel tube products, providing the industry with multi-material and multi-specification product solutions.

Organization characteristics and performance basis of austenitic stainless steel

Austenitic stainless steel is a face-centered cubic structure material dominated by austenite phase. It has a stable structure at room temperature and will not undergo brittle phase transformation. Typical chemical compositions include high contents of chromium (Cr) and nickel (Ni), of which chromium provides oxidation resistance and nickel enhances the toughness and corrosion resistance of the material.

Jiangsu Jend Tube Co., Ltd. provides austenitic stainless steel seamless tubes covering multiple grades, including:

TP304/TP304L/TP304H

TP316/TP316L/TP316Ti

TP321(H), TP347(H)

TP310S, TP317 and other high temperature or enhanced series

These materials are in line with international standards (such as ASTM, ASME, EN, etc.) and can meet the needs of tubeline systems under different pressure levels, temperature ranges and media environments.

Product Manufacturing Range and Customization Capabilities

According to the application requirements of the actual project, austenitic stainless steel tubes often involve a variety of wall thickness and diameter specifications. The seamless tube manufacturing specifications supported by Jiangsu Jend Tube Co., Ltd. are:

Outer diameter range: 3.18mm ~ 406.4mm

Wall thickness range: 0.3mm ~ 20mm

Single length: up to 25 meters

The wide range of manufacturing sizes provides a flexible material basis for different scenarios (such as heat exchangers, boilers, food tubelines, and pressure vessels). In addition, the company also accepts special customized services, such as ultra-thin wall tubes, thickened tubes, pickling passivation surface treatments, customized cutting lengths, etc., to adapt to engineering projects with higher requirements.

Typical application areas and demand trends

Austenitic stainless steel tubes have many performance advantages and are used in many industries:

Petrochemical and chemical equipment

TP316L and TP321 series are often used to transport media in acidic, alkaline or chloride ion environments, and can operate for a long time in heat exchangers, storage tanks and reactors. The ability to resist stress corrosion cracking is the focus of the chemical industry.

Food and pharmaceutical industry

TP304 and TP316 sanitary tubes are widely used in dairy products, beverages, water treatment and injection production systems due to their easy-to-clean and non-contamination properties.

High-temperature structural components

TP310S is suitable for high-temperature flue gas or combustion systems. It has strong high-temperature strength and oxidation resistance and is widely used in heat treatment furnaces, power plant boilers and other equipment.

Pressure piping system

TP347H and TP321H are commonly used in high-temperature and high-pressure working environments such as power plants and fertilizer plants, and can withstand strong thermal cycle stress and oxidative corrosion environments.

With the continuous upgrading of industrial standards, customers have increasingly higher requirements for material lists, quality traceability, and surface treatment of tubes, which drives manufacturers to develop in a more precise and standardized direction.

Quality control system from production to export

Jiangsu Jend Tube Co., Ltd. has established a complete quality control process in material procurement, processing flow, heat treatment, dimensional correction and non-destructive testing. The main processes include cold drawing, cold rolling, annealing, pickling, straightening and ultrasonic testing, eddy current testing, water pressure testing, etc., to ensure that each tube meets customer requirements.

Since its establishment, the company has actively expanded overseas markets, and its products have been exported to more than 50 countries and regions including Europe, America, Southeast Asia, and the Middle East, and gradually established an international supply chain system based on customer demand. For European and American customers, the company cooperates with ASTM A213/A269/A312 series standards; for projects in Southeast Asia and the Middle East, it supports third-party testing (such as SGS, TÜV, BV) to issue quality certificates.

Technical capabilities and future development directions

Jiangsu Jend Tube Co., Ltd. focuses on technology accumulation and innovative applications. In the future, austenitic stainless steel tubes have great development potential in the following directions:

Research and development of low-carbon/ultra-low-carbon austenitic stainless steel to reduce the risk of intergranular corrosion;

High-performance alloy alternatives suitable for emerging industries such as hydrogen energy and seawater desalination;

Clean manufacturing and surface modification technology to improve material cleanliness and durability;

More precise dimensional control and surface quality management to meet the needs of precision manufacturing fields such as aerospace and medical equipment.

The company will also continue to expand its material database and testing capabilities to help products adapt to a wider range of application scenarios.

Technical characteristics and engineering adaptability of austenitic stainless steel tubes

Among many metal materials, austenitic stainless steel tubes are widely used in multiple key industrial systems due to their stable structure, strong corrosion resistance and moderate processing performance. From basic chemical tubelines to pharmaceutical production lines with high cleanliness requirements, austenitic stainless steel has penetrated almost all fluid transportation or structural support scenarios with high requirements for safety and long-term stability. As a production-oriented enterprise with stainless steel seamless tube manufacturing as its core, Jiangsu Jend Tube Co., Ltd. has continuously expanded the material combination and specification coverage on the austenitic stainless steel tube product line in recent years to adapt to the changing industrial needs at home and abroad.

Organization mechanism and material behavior of austenitic stainless steel

Austenitic stainless steel belongs to the face-centered cubic crystal structure, maintains austenite stable state at room temperature, and is non-magnetic. The typical alloy element combination in this type of steel is high chromium (generally above 18%) and high nickel (above 8%), which can effectively improve the corrosion resistance and processing adaptability of the material. Common grades include TP304, TP316, TP321, TP347, TP310S, etc., which have balanced performance in thermal stability, formability, weldability, etc.

Jiangsu Jend Tube Co., Ltd. can provide the following commonly used austenitic seamless steel tube series:

TP304/TP304L/TP304H: commonly used in general corrosive environments from room temperature to medium temperature;

TP316/TP316L/TP316Ti: enhanced resistance to chloride corrosion, suitable for neutral to weak acid media;

TP310S: has good high-temperature oxidation resistance;

TP321/TP347 series: contains titanium or niobium stabilizing elements, used in intergranular corrosion resistance occasions.

The company is also involved in heat-resistant materials with special composition ratios such as TP317 and TP347H to adapt to complex environments such as pressure vessels and high-temperature furnaces.

Manufacturing capabilities: from standard products to special customization

Modern industrial projects require not only reliable performance of stainless steel tubes, but also higher personalized requirements in terms of specifications, length, wall thickness tolerance, surface treatment, etc. The austenitic stainless steel seamless tubes provided by Jiangsu Jend Tube Co., Ltd. cover the following manufacturing capabilities:

Outer diameter range: 3.18mm to 406.4mm

Wall thickness range: 0.3mm to 20mm

Single tube length: up to 25000mm

Support multiple standards: including ASTM, ASME, GB/T, EN, JIS, etc.

According to customer needs, the company can provide fixed-length cutting, pickling and passivation, mechanical polishing, internal and external weld cleaning, non-destructive testing, pressure testing and other supporting processes. At the same time, for non-standard equipment supporting projects, the company also supports the flexible manufacturing of small batches and composite structure tubes.

Analysis of typical application areas

Due to the corrosion resistance and structural stability of austenitic stainless steel, it is widely used in the following industrial sectors:

Energy engineering

In thermal power, nuclear power, solar thermal power generation and other projects, TP321 and TP347H are often used as superheater, reheater and drum connecting tubes because they can adapt to long-term high-temperature operation and resist creep failure.

Food and sanitary piping systems

In the dairy, beverage, water treatment and pharmaceutical industries, TP304L and TP316L are often used in sanitary tube networks, and their corrosion resistance can meet the CIP (online cleaning) and SIP (online sterilization) operating procedures.

Ocean and shipbuilding industry

TP316Ti and TP317 are often used in offshore structures, platform water supply, seawater desalination and other projects, and have good resistance to chloride ion corrosion.

Chemical and fertilizer industry

tubelines often transport fluids containing acid and alkali components, and have high requirements for inner wall corrosion resistance. TP316L and TP317 are one of the widely used grades, suitable for production lines such as urea synthesis and sulfuric acid process.

High-temperature gas delivery system

TP310S has strong high-temperature oxidation resistance and is frequently used in furnace tubes and heat treatment devices, especially in flue gas ducts and burner areas.

Quality assurance and international supply experience

Jiangsu Jend Tube Co., Ltd. adheres to an integrated quality control process from raw material screening, smelting, cold processing, heat treatment to finished product inspection. The company has a complete testing system, including:

Eddy current testing, ultrasonic testing, X-ray flaw detection

Chemical composition analysis, metallographic testing, intergranular corrosion testing

Hydraulic pressure testing and air tightness testing

The company's products have been exported to more than 50 countries and regions in Europe, America, Southeast Asia, the Middle East, etc., and support the inspection process of third-party testing agencies (such as SGS, BV, TÜV), and cooperate with the material certificates (MTC), proof of origin, pressure vessel material registration and other information required for various engineering projects to meet the procurement compliance of international projects.

Development trend of austenitic stainless steel tubes

With the strengthening of environmental protection regulations, the expansion of new energy industries and the upgrading of intelligent manufacturing, austenitic stainless steel tubes are facing new demand forms:

Material upgrade: such as the development of low-carbon and ultra-low-carbon austenitic steel grades to improve welding stability;

Clean manufacturing: by improving the accuracy of pickling and polishing, to meet the needs of industries such as biomedicine that are more sensitive to particles and impurities;

Composite structure exploration: such as the promotion of bimetallic composite tubes to find a balance between cost and performance;

More stringent quality traceability system: especially in the European and North American markets, promote enterprises to improve the production chain recording system.

Jiangsu Jend Tube Co., Ltd. is gradually expanding its capabilities in the above directions, reserving sufficient technology and production capacity space for future market changes.

한국어

한국어 русский

русский عربى

عربى