We understand the challenges of various industries, and manufacture reliable quality products through top-notch equipment and professional production technology, so that customers' ideas can be quickly realized.

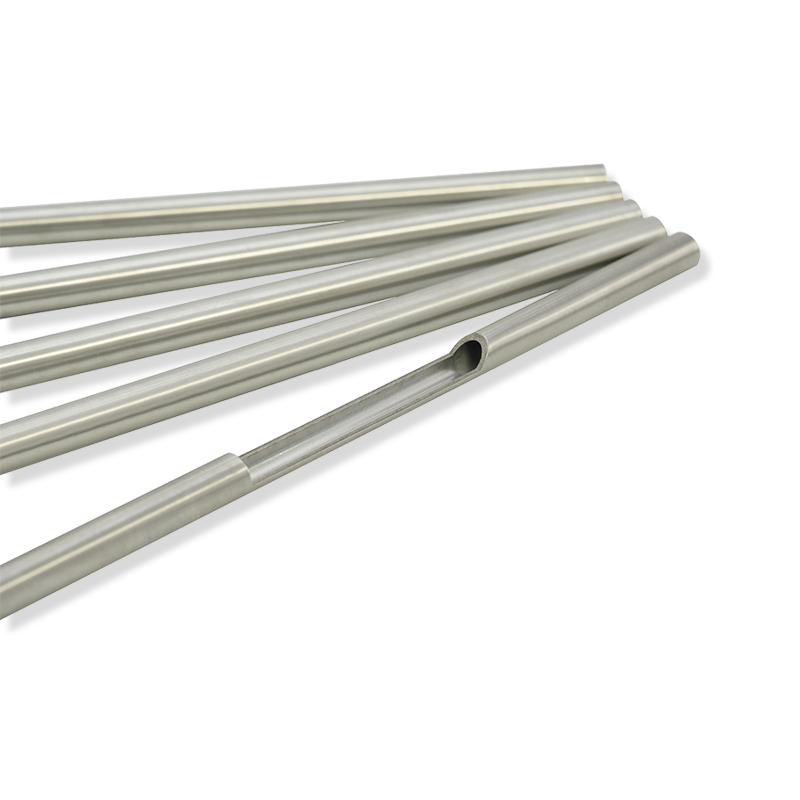

6Mo alloy pipe, known commercially as 254 SMO™, is a high-alloy austenitic stainless steel engineered for maximum resistance to pitting and crevice corrosion. Its elevated chromium, molybdenum, and nitrogen content makes it highly suitable for chloride-rich environments, including brackish water, seawater, pulp mills, bleach plants, and other high-chloride industrial processes.

Due to its compatibility with conventional austenitic stainless steels, 6Mo alloy is often used as a replacement in large structures where 316L or 317L stainless steels have failed due to pitting, crevice corrosion, or chloride stress corrosion cracking. Although significantly stronger than common austenitic grades, the alloy retains high ductility and impact toughness.

254 SMO™ also offers excellent weldability and formability, capable of cold bending to very small radii without cracking, making it highly versatile in critical and complex piping systems.

한국어

한국어 русский

русский عربى

عربى