We understand the challenges of various industries, and manufacture reliable quality products through top-notch equipment and professional production technology, so that customers' ideas can be quickly realized.

about Jiangsu Jend Tube Co.,Ltd.

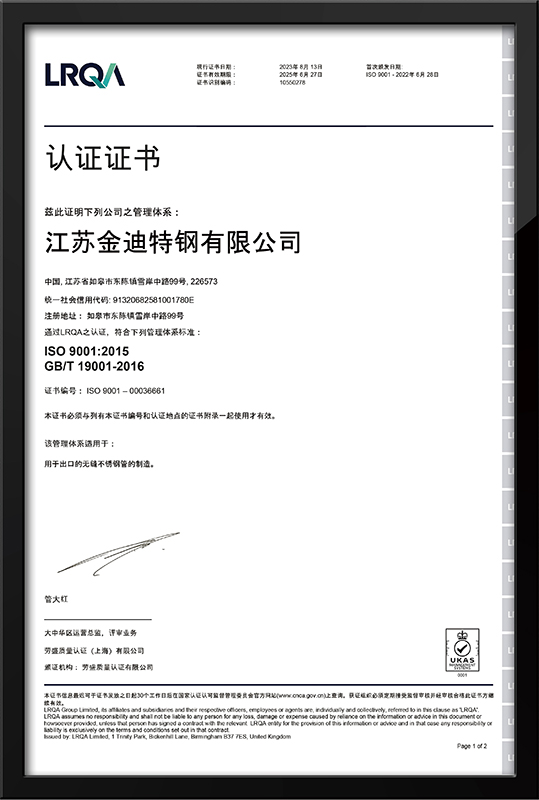

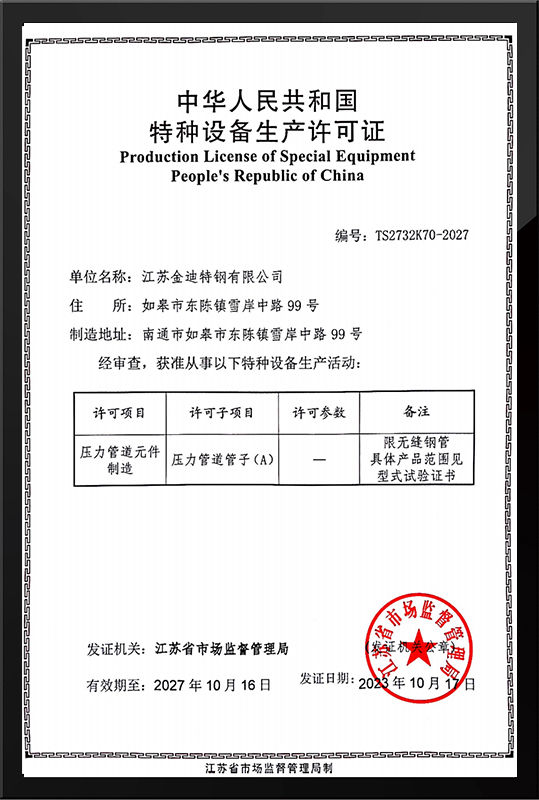

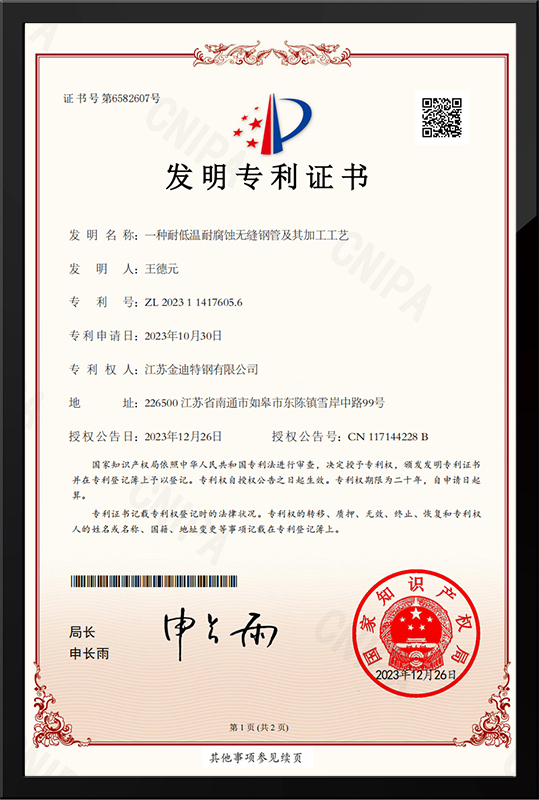

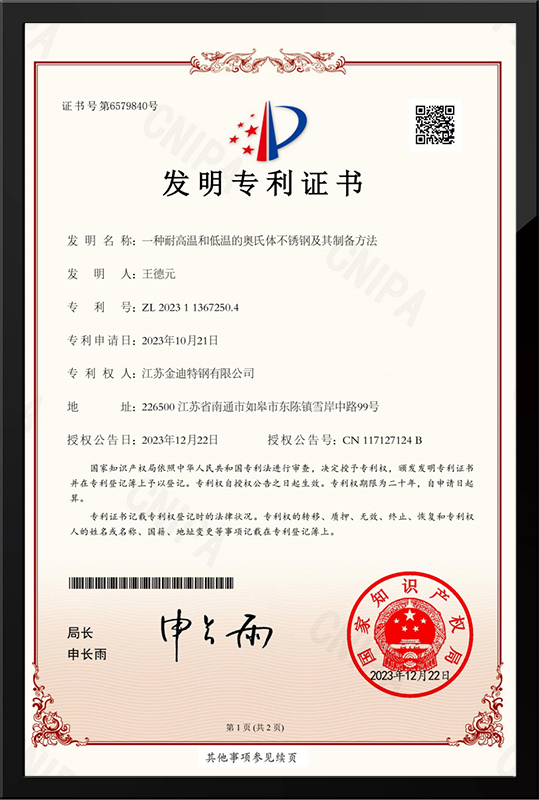

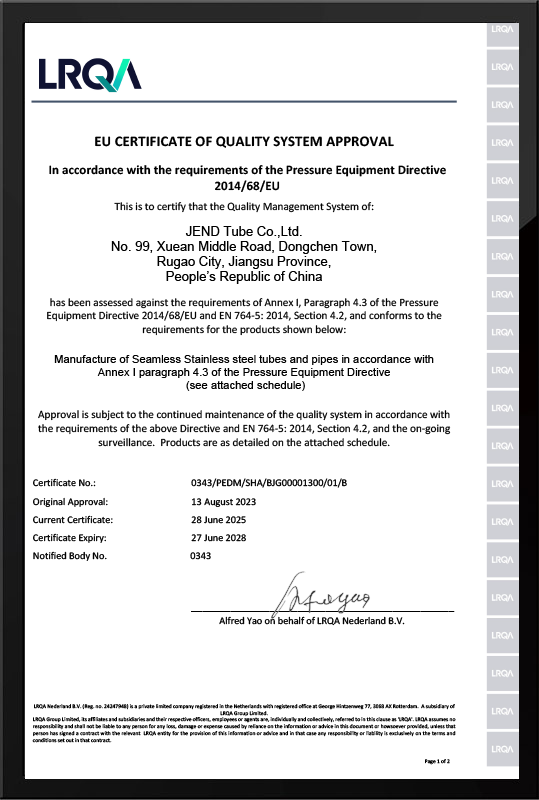

As China Nickel-Based Alloy Stainless Steel Tube Manufacturers and Seamless Nickel-Based Alloy Stainless Steel Tube Suppliers, Established in 2011 and is a manufacturing enterprise with a complete manufacturing cycle from raw material selection to finished product delivery. The company currently has more than 100 employees, covers an area of 30015 square meters, and has a registered captial of 48 million yuan, annual production capacity of 3800 tons. The company has passed ISO9001:2015 quality certification, domestic pressure vessel TS certification, and foreign pressure vessel PED certification. With rich experience and mature technology, we have been expanding our market internationally. At present, our products are exported to more than 50 countries and regions including Europe, America, Southeast Asia, and the Middle East. The company adheres to different production norms and standards such as the American standard (ASTM), the European standard (EN), the German standard (DIN), the Japanese standard (JIS), the Russian standard (GOST), and the Chinese standard (GB). Our company specializes in and customizes various specifications of Martensite TP410 (0Cr13, 1Cr13), Ferrite TP405 (1Cr13Al), TP430 (1Cr17), TP444 (0Cr18Mo2), TP439, TP409 (0Cr11Ti), It is also proficient in manufacturing Austenitic seamless stainless steel pipes of series such as TP304(L/H),TP316(L/H/Ti),TP310S,TP317,TP321(H) and TP347(H). Duplex such as S31803、S2205、S32750、S32304, and Nickel-based alloys Monel400, Monel600, Monel800, GH3030, 904L,Inconel 625,etc. The company mainly produces seamless steel pipes with the following specifications: outer diameter: 3.18mm to 406.4mm, wall thickness: 0.3mm to 20mm, and the longest length is 25000mm. Additionally, it can customize seamless steel pipes with special materials and specifications according to customer requirements. The company attaches great importance to scientific innovation. The staff of the company vigorously develop technological research and development. Jiangsu Jend Tube Co.,Ltd.will continuously accumulate professional knowledge and capabilities, striving to become a leader in the domestic market and even the world market. Strive to be the most reassurring pipe manufacturing enterprise for customers.

news

centerAuthentic reliable quality naturally stands out and fears no comparison.

All news-

Why is Austenitic Stainless Steel Tube the Best Choice for High-Corrosion Environments

Unveiling Stainless Steel: From Alloy Definition to the Core of Austenite Stainless steel is not a single material but a vast family of iron-based alloys. The c

-

Why is the Austenitic Stainless Steel Tube the Top Choice for Industrial Piping

In the realm of modern industrial manufacturing and fluid transport, the selection of stainless steel tubing directly dictates the safety and longevity of the e

-

Which Stainless Steel Tube Type is Best for Your Project? (304 vs 316 vs 2205)

Austenitic Stainless Steel Tubing Austenitic stainless steel tubing is the most widely used category of Stainless Steel Tube in both industrial and civil fields

-

Why Does My Stainless Steel Tube Still Rust? The Truth About Ferritic Grades

1. Corrosion Resistance Principles of Ferritic Stainless Steel The corrosion resistance of ferritic stainless steel is primarily due to its high Chromium conten

INDUSTRY KNOWLEDGE EXTENSION

Manufacturing Challenges and Practical Paths of Nickel-Based Alloy Stainless Steel Tubes

Among many metal materials, nickel-based alloys are widely used in key fields such as petroleum, chemical industry, nuclear power, and marine engineering due to their good corrosion resistance and high temperature performance. Among the many nickel-based alloy product forms, seamless stainless steel tubes belong to a category with higher technical requirements. Not only are the materials special, but they are also difficult to process. Jiangsu Jend Tube Co., Ltd. has accumulated a reference technical system and practical cases in the manufacture of nickel-based alloy stainless steel tubes with its in-depth research and production experience in the field of alloy tubes over the years.

Why are nickel-based alloy tubes difficult to process?

Compared with common stainless steel or carbon steel, nickel-based alloys have significantly different physical and chemical properties. For example, the high nickel content in the alloy will lead to a stronger creep resistance of the material at high temperatures, which is beneficial for heat-resistant equipment, but it also means that in processes such as forging, cold drawing, and heat treatment, the work hardening is significant, and cracks or surface defects are prone to occur.

Jiangsu Jend Tube Co., Ltd. found in actual production that some nickel-based alloys (such as Monel 400 and Inconel 625) have high requirements for lubrication and deformation rate control during cold processing. If lubrication is insufficient or cold deformation is excessive, microcracks or metallographic structure abnormalities may occur, affecting product reliability.

Enterprises usually adopt a multi-step forming strategy, that is, a one-time large deformation is disassembled into multiple small and medium deformation steps, combined with intermediate annealing treatment, which helps to reduce stress concentration. In addition, for different grades, the company has established a matching heat treatment curve database to ensure the homogenization and stability of the organization.

Material ratio and quality consistency control

There are many types of nickel-based alloys, and the ratio of each material has a great influence on the performance. For example, a slight deviation in the ratio of iron, nickel and chromium in Incoloy 800 may cause intergranular corrosion sensitivity; GH3030 (a high-temperature alloy) needs to be extremely precise when controlling the ratio of carbon and titanium, otherwise it is easy to affect the creep strength.

Jiangsu Jend Tube Co., Ltd. has introduced multiple quantitative direct reading spectrometers and carbon-sulfur analyzers to conduct 100% composition re-inspection of incoming raw materials to ensure that the alloy composition is within the specified fluctuation range. In addition, the company has the ability to adjust small batch formulas and can fine-tune the material ratio according to the special environmental requirements (such as chloric acid and high sulfur conditions) proposed by customers.

Dimensional accuracy and internal and external surface treatment process

Nickel-based alloy tubes are usually used in extreme environments and have high requirements for working condition stability, which puts forward high standards for the dimensional accuracy and surface state of the tubes. Especially in equipment such as heat exchangers and reaction towers, uneven tube wall thickness or rough inner surface may lead to reduced thermal efficiency or local corrosion.

Jiangsu Jend Tube Co., Ltd. uses an automatic ultrasonic thickness measurement system to monitor the uniformity of wall thickness in real time. In terms of internal surface treatment, the company has introduced a variety of solutions such as pickling passivation, mechanical polishing and electrolytic polishing to meet different usage requirements. In addition, for small-diameter thin-walled nickel-based tubes, directional perforation and core guide technology are specially equipped to improve processing stability.

Customer customization capabilities and engineering docking services

Unlike mass production, the application of nickel-based alloy tubes is often small-batch and highly customized. For example, the Inconel 690 tubes required by nuclear power projects may have special specifications in thickness, length and even joint form. Jiangsu Jend Tube Co., Ltd. provides one-stop customization services, from alloy selection, size design, test standard docking, to finished product packaging and delivery, all of which are fully participated by a team of professional engineers.

It is worth mentioning that the company can provide third-party testing and certification (such as TÜV, BV, SGS) and customized production under multiple standard systems such as EN, ASTM, GB, etc., which is convenient for customers to carry out global project matching.

Future development trend: higher grade, smaller tolerance, wider standard

With the continuous development of high-end equipment manufacturing, the market demand for nickel-based alloy stainless steel tubes is also changing. On the one hand, higher-grade new alloy materials are being developed and applied, such as Inconel 718, Alloy 59, etc., challenging the new limits of manufacturing processes; on the other hand, some precision industries have begun to put forward micron-level requirements for tolerance control.

Jiangsu Jend Tube Co., Ltd. has begun to lay out intelligent manufacturing modules, including the introduction of robot operation units, MES management and control systems, and intelligent testing equipment to improve production stability and traceability, and prepare for future high-precision and high-reliability needs.

Applicability of nickel-based alloy stainless steel tubes in highly corrosive environments

With the development of industrial technology, engineering has put forward more and more complex requirements for the use environment of materials, especially in high temperature, high corrosion and high stress occasions. Traditional stainless steel materials have gradually failed to meet the long-term stability requirements of some key applications. In this context, nickel-based alloy stainless steel tubes have gradually entered people's field of vision and have been applied in many industries such as petrochemical, marine engineering, power, aerospace, etc.

Jiangsu Jend Tube Co., Ltd. is a tubeline manufacturing company established in 2011. It has a complete production system from raw material selection to finished product delivery. It is committed to providing seamless steel tube products of various materials and specifications, including Monel400, Inconel625, 904L, GH3030 and other nickel-based alloy stainless steel tubes. Relying on its own processing capabilities and technical accumulation, the company has exported its products to more than 50 countries and regions, forming a relatively complete international supply network.

What is nickel-based alloy stainless steel tube

Nickel-based alloy stainless steel tube refers to an alloy tube formed by reasonably matching chromium, iron, molybdenum, copper and other elements with a high nickel content in its alloy system (generally more than 30%). This type of tube has good corrosion resistance, especially in high temperature and highly corrosive media. At the same time, its structural stability is also high, and it can maintain physical properties under drastic temperature differences or long-term stress.

Common nickel-based alloy stainless steel tube models include:

Inconel 625: nickel, chromium, and molybdenum are the main components, suitable for high temperature, high pressure and highly corrosive environments.

Monel 400: nickel-copper is used as the matrix, often used in marine engineering to resist salt spray and seawater corrosion.

904L: Austenitic alloy steel with high nickel, chromium and molybdenum content, suitable for acidic environments such as sulfuric acid and phosphoric acid media.

GH3030 (Ni-Cr-based alloy): suitable for high-temperature parts of aircraft engines.

Key points for processing and manufacturing of nickel-based alloy stainless steel tubes

The thermal strength and chemical stability of nickel-based alloys make it more difficult to process than traditional stainless steel materials, so higher technical requirements are required from smelting to finished products. Jiangsu Jend Tube Co., Ltd. has accumulated a relatively mature process flow in the long-term manufacturing process:

Smelting and forging: Nickel-based alloy raw materials need to be melted by vacuum induction or electroslag remelting to control the non-metallic inclusion content and improve the purity of the material.

Piercing and rolling: Nickel alloy materials have low plasticity during the piercing stage, and slow and high-temperature piercing processes are usually used to avoid cracks.

Heat treatment: Controlling the heat treatment process is a key step to stabilize the grains and avoid intergranular corrosion, especially when dealing with acid-resistant alloys such as 904L and Inconel 625, the process window is narrow.

Pickling and surface treatment: The surface oxide layer of nickel alloy is not easy to remove, and a special pickling solution must be used for uniform treatment to ensure the clean surface of the tube.

Detection and testing: Non-destructive testing (such as eddy current, ultrasonic) and mechanical property testing must be fully covered to ensure the stability of the product during long-term service.

Practical application analysis of nickel-based alloy tubes

Due to its comprehensive performance in high temperature resistance, corrosion resistance and fatigue resistance, nickel-based alloy stainless steel tubes are widely used in the following scenarios:

Oil and gas industry: When transporting high-sulfur natural gas or high-pressure gas containing CO₂, ordinary stainless steel tubes may face rapid corrosion, while nickel-based alloys can effectively extend the service life.

Chemical industry equipment: used for internal piping of reactors, heat exchangers, condensers and other equipment, which is more stable when facing high-concentration sulfuric acid, hydrochloric acid or other corrosive solutions.

Nuclear power and thermal energy equipment: used for heat-resistant and corrosion-resistant tubelines in the primary circuit and steam generator of nuclear power plants.

Marine engineering: Under conditions such as long-term immersion in seawater and salt spray, traditional steel is prone to pitting or crevice corrosion, while Monel alloy has better stability under such conditions.

Future development trends and corporate practices

With the development of new fields such as renewable energy, seawater desalination, and hydrogen energy utilization, the demand for high-performance metal tubes is growing. Especially for high-temperature and high-pressure conditions, the market space for nickel-based alloys is still expanding. Jiangsu Jend Tube Co., Ltd. plans to continue to expand its product line of high-alloy materials and improve the efficiency and consistency of batch manufacturing by introducing automated manufacturing equipment and strengthening process control. The company is also exploring cooperation with international customers to propose customized solutions for different environments, including material ratio adjustment, tubeline corrosion life simulation, and integrated supply of complex structural components.

한국어

한국어 русский

русский عربى

عربى