Jiangsu Jend Tube Co.,Ltd. is GH3030 nickel-based alloy single-phase austenitic tube Manufacturers and GH3030 nickel-based alloy single-phase austenitic tube Factory, Established in 2011 and is a manufacturing enterprise with a complete manufacturing cycle from raw material selection to finished product delivery. The company currently has more than 100 employees, covers an area of 30015 square meters, and has a registered captial of 48 million yuan, annual production capacity of 3800 tons.

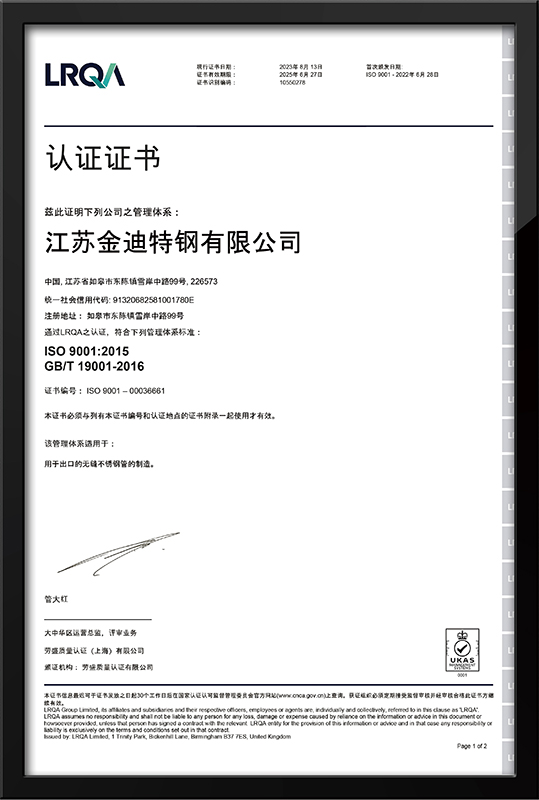

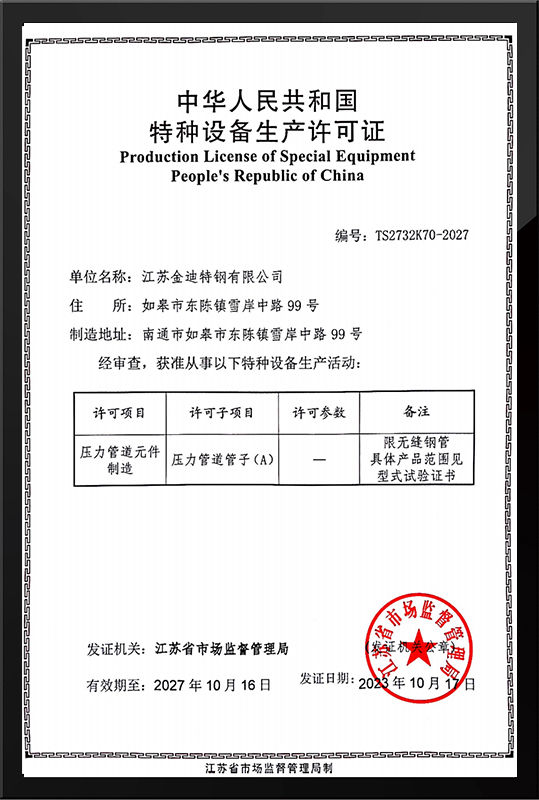

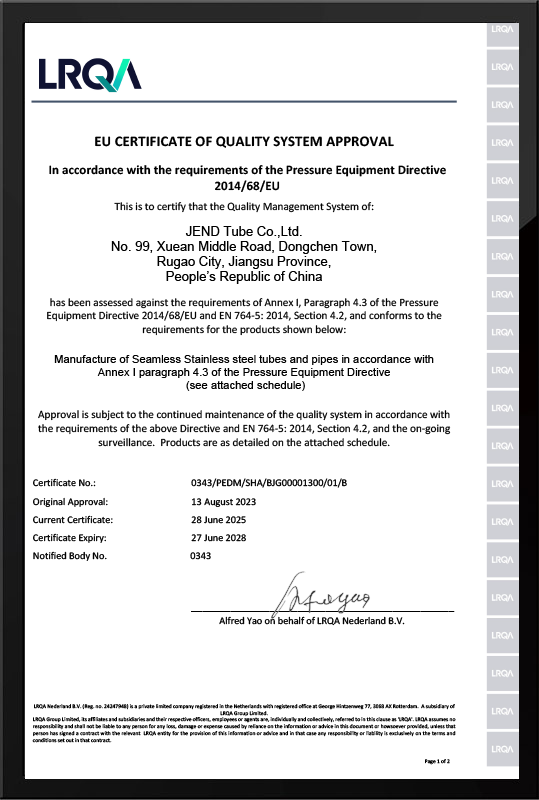

The company has passed ISO9001:2015 quality certification, domestic pressure vessel TS certification, and foreign pressure vessel PED certification. With rich experience and mature technology, we have been expanding our market internationally. At present, our products are exported to more than 50 countries and regions including Europe, America, Southeast Asia, and the Middle East.

The company adheres to different production norms and standards such as the American standard (ASTM), the European standard (EN), the German standard (DIN), the Japanese standard (JIS), the Russian standard (GOST), and the Chinese standard (GB).

Our company specializes in and customizes various specifications of Martensite TP410 (0Cr13, 1Cr13), Ferrite TP405 (1Cr13Al), TP430 (1Cr17), TP444 (0Cr18Mo2), TP439, TP409 (0Cr11Ti), It is also proficient in manufacturing Austenitic seamless stainless steel pipes of series such as TP304(L/H),TP316(L/H/Ti),TP310S,TP317,TP321(H) and TP347(H). Duplex such as S31803、S2205、S32750、S32304, and Nickel-based alloys Monel400, Monel600, Monel800, GH3030, 904L,Inconel 625,etc.

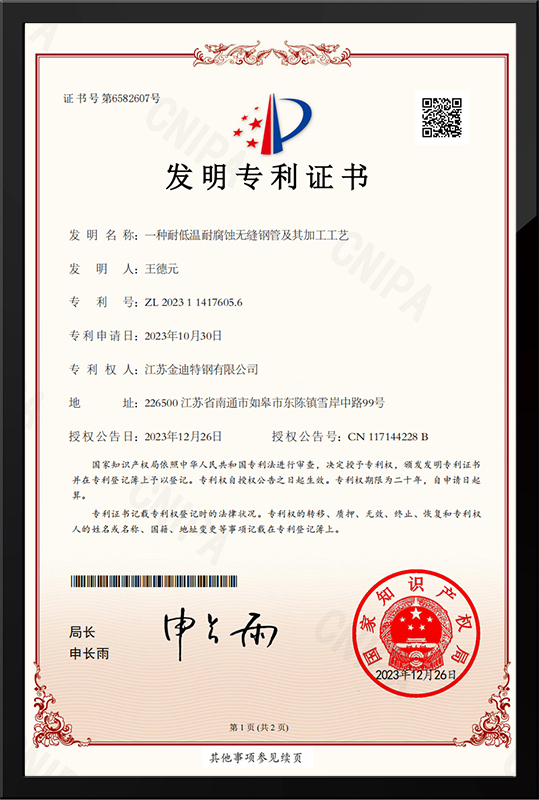

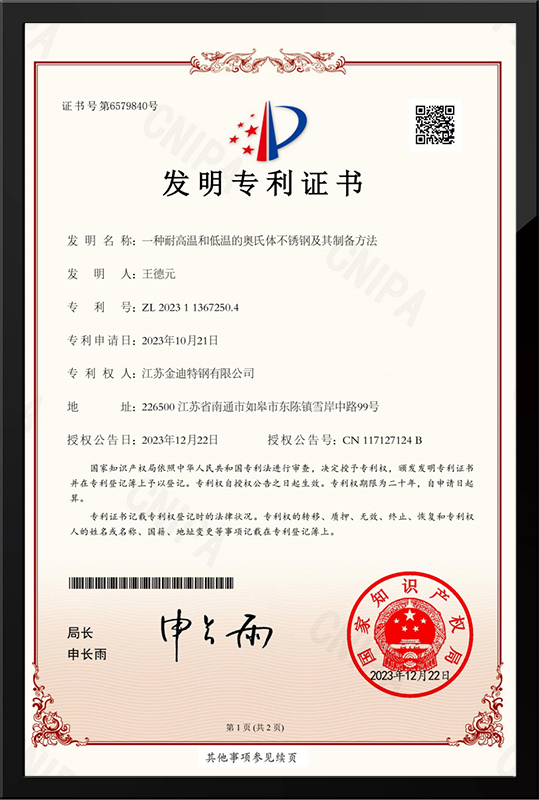

The company mainly produces seamless steel pipes with the following specifications: outer diameter: 3.18mm to 406.4mm, wall thickness: 0.3mm to 20mm, and the longest length is 25000mm. Additionally, it can customize seamless steel pipes with special materials and specifications according to customer requirements. The company attaches great importance to scientific innovation. The staff of the company vigorously develop technological research and development.

Jiangsu Jend Tube Co.,Ltd.will continuously accumulate professional knowledge and capabilities, striving to become a leader in the domestic market and even the world market. Strive to be the most reassurring pipe manufacturing enterprise for customers.

한국어

한국어 русский

русский عربى

عربى