We understand the challenges of various industries, and manufacture reliable quality products through top-notch equipment and professional production technology, so that customers' ideas can be quickly realized.

about Jiangsu Jend Tube Co.,Ltd.

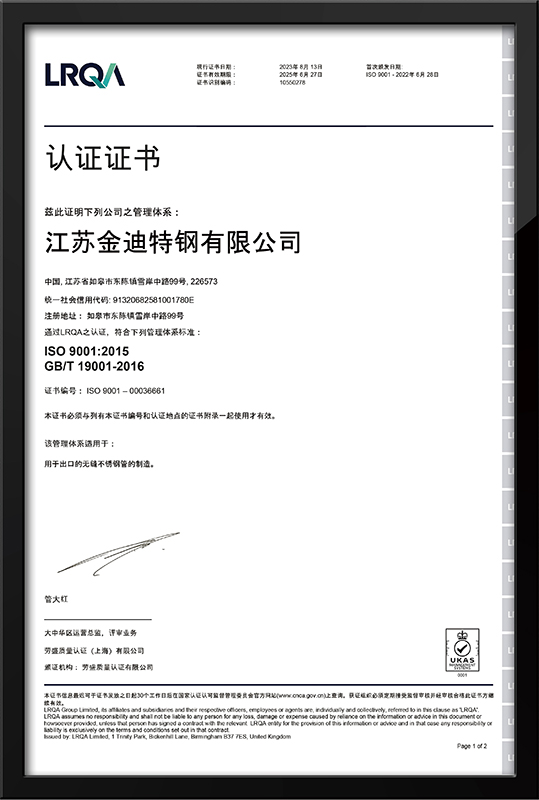

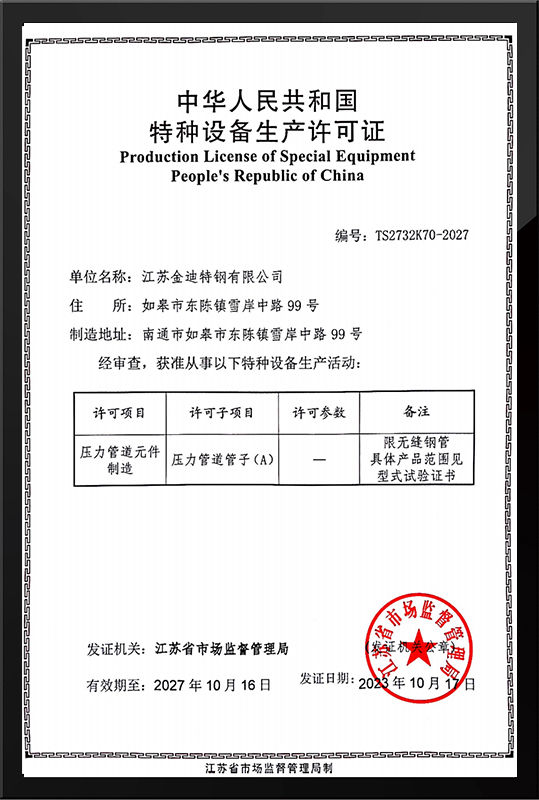

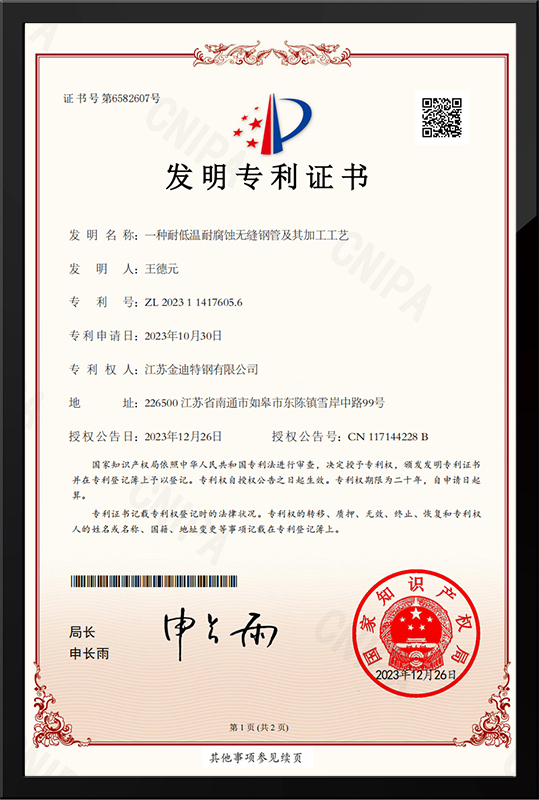

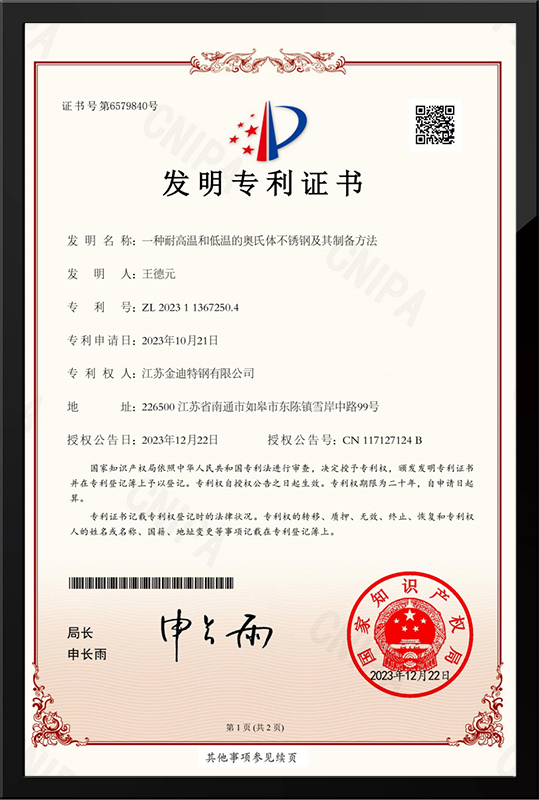

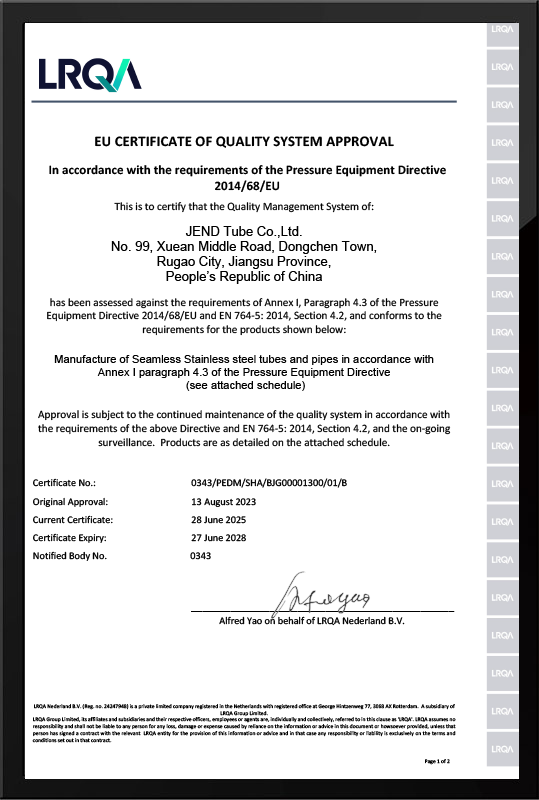

As China AP Tube Manufacturers and Stainless Steel AP Tube Suppliers, Established in 2011 and is a manufacturing enterprise with a complete manufacturing cycle from raw material selection to finished product delivery. The company currently has more than 100 employees, covers an area of 30015 square meters, and has a registered captial of 48 million yuan, annual production capacity of 3800 tons. The company has passed ISO9001:2015 quality certification, domestic pressure vessel TS certification, and foreign pressure vessel PED certification. With rich experience and mature technology, we have been expanding our market internationally. At present, our products are exported to more than 50 countries and regions including Europe, America, Southeast Asia, and the Middle East. The company adheres to different production norms and standards such as the American standard (ASTM), the European standard (EN), the German standard (DIN), the Japanese standard (JIS), the Russian standard (GOST), and the Chinese standard (GB). Our company specializes in and customizes various specifications of Martensite TP410 (0Cr13, 1Cr13), Ferrite TP405 (1Cr13Al), TP430 (1Cr17), TP444 (0Cr18Mo2), TP439, TP409 (0Cr11Ti), It is also proficient in manufacturing Austenitic seamless stainless steel pipes of series such as TP304(L/H),TP316(L/H/Ti),TP310S,TP317,TP321(H) and TP347(H). Duplex such as S31803、S2205、S32750、S32304, and Nickel-based alloys Monel400, Monel600, Monel800, GH3030, 904L,Inconel 625,etc. The company mainly produces seamless steel pipes with the following specifications: outer diameter: 3.18mm to 406.4mm, wall thickness: 0.3mm to 20mm, and the longest length is 25000mm. Additionally, it can customize seamless steel pipes with special materials and specifications according to customer requirements. The company attaches great importance to scientific innovation. The staff of the company vigorously develop technological research and development. Jiangsu Jend Tube Co.,Ltd.will continuously accumulate professional knowledge and capabilities, striving to become a leader in the domestic market and even the world market. Strive to be the most reassurring pipe manufacturing enterprise for customers.

news

centerAuthentic reliable quality naturally stands out and fears no comparison.

All news-

Why is Austenitic Stainless Steel Tube the Best Choice for High-Corrosion Environments

Unveiling Stainless Steel: From Alloy Definition to the Core of Austenite Stainless steel is not a single material but a vast family of iron-based alloys. The c

-

Why is the Austenitic Stainless Steel Tube the Top Choice for Industrial Piping

In the realm of modern industrial manufacturing and fluid transport, the selection of stainless steel tubing directly dictates the safety and longevity of the e

-

Which Stainless Steel Tube Type is Best for Your Project? (304 vs 316 vs 2205)

Austenitic Stainless Steel Tubing Austenitic stainless steel tubing is the most widely used category of Stainless Steel Tube in both industrial and civil fields

-

Why Does My Stainless Steel Tube Still Rust? The Truth About Ferritic Grades

1. Corrosion Resistance Principles of Ferritic Stainless Steel The corrosion resistance of ferritic stainless steel is primarily due to its high Chromium conten

INDUSTRY KNOWLEDGE EXTENSION

The key role of manufacturing process and quality control in the production of seamless steel tubes

In the industrial field, workmanship refers not only to the external quality of the product itself, but also to the control ability and detail management in the manufacturing process. For a company that specializes in the production of seamless steel tubes, especially Jiangsu Jend Tube Co., Ltd., the process level is directly related to the stability and competitiveness of the company in the global market.

The meaning of workmanship in the tube industry

In the tube production environment, the process level includes the following dimensions:

Raw material procurement and composition control: the stability of the material lays the foundation for the quality of the tube;

Processing process technology: the execution quality of multiple key processes such as perforation, heat treatment, rolling, cold drawing, welding, etc.;

Testing methods and standard implementation: such as dimensional tolerances, mechanical properties, surface defects, etc.;

Detail processing capabilities: internal cleaning, surface treatment, packaging, protection, etc.;

Technical solutions and customer communication: including customization capabilities, trial production, engineering support and other links.

Workmanship represents the management level and implementation capabilities of the company in process details.

Key manifestations of process level

1.Raw materials and ingredient management

Jiangsu Jend Tube Co., Ltd. emphasizes the purchase of internationally certified steel billets and performs spectral analysis on each batch of raw materials. By tracking the smelting batch number (Heat No.) and chemical analysis results, key elements such as Cr, Ni, Mo, Cu, etc. of alloy tubes such as nickel-based alloys, stainless steel, and duplex steel are ensured to be within a reasonable range. This process reflects the importance of original control in the process level.

2.Precision of processing links

From steel billets to seamless tubes, it is necessary to go through steps such as piercing, hot rolling, and cold drawing. Each step has precision control requirements, especially for wall thickness consistency, outer diameter stability, and uniformity of organization. Jiangsu Jend Tube Co., Ltd. combines online thickness measurement equipment, constant temperature furnaces, automatic control networks, etc. to achieve real-time monitoring of process parameters and reduce human deviations.

3.Surface treatment and cleaning

Surface defects are one of the important factors affecting customer recognition. The company improves the uniformity and cleanliness of the tube surface through a phased combination of pickling, mechanical polishing, and passivation. At the same time, the CTF closed packaging method is used to isolate external pollution and improve the customer's on-site installation efficiency.

Quality inspection and process level inspection

1.Non-destructive testing system

Ultrasonic flaw detection: full-length scanning of internal cracks in the tube;

Eddy current detection: designed for the non-magnetic characteristics of nickel-based alloys and duplex steel;

Water pressure and airtightness test: simulate the use pressure state to detect leakage risks.

These means cooperate with each other to form a complete quality inspection system, and reflect the company's rigorous attitude in process execution and traceability of details.

2.Mechanical properties and dimensional inspection

Tensile, hardness, bending: batch sampling test and filing to provide a basis for subsequent on-site verification;

Dimension tolerance control: cooperate with precision calipers, three-coordinate measuring instruments, etc. to ensure that each batch of products meets customer technical standards.

Through these methods, workmanship has clear evidence from the "seeing", "touching" and "testing" of the product.

Technical team and talent training

The quality of the manufacturing process depends not only on equipment, but also on a team with professional skills. Jiangsu Jend Tube Co., Ltd. has the following advantages:

Process technology training: Regular internal and external training are held to strengthen employees' process understanding and operation specifications;

Quality learning mechanism: Establish a quality feedback system, and technical team meetings will discuss and improve bad projects or customer complaints;

R&D support system: Process experts participate in the trial production of new tubes and new processes, provide optimization suggestions and track the results.

This mechanism allows the workmanship to be continuously maintained and improved.

Meet the process expectations of international customers

In cross-border trade, customers pay attention to process execution and supply consistency:

Standard certification coverage: ASTM, EN, ASME, GB and other standards have different requirements, and companies can provide corresponding reports;

Third-party testing and quality inspection guarantee: The test reports of SGS, TÜV, BV and other institutions have become an important basis for downstream purchasing companies to inspect the factory;

Traceable documents and technical support: From the source of materials to production batches, process parameters, test results, etc., there are records, and when customers need technical docking, complete materials can be provided.

These measures have enhanced customer trust and increased willingness to cooperate.

Future process improvement direction

Digital factory construction

Use MES system to track the entire process, and gradually introduce industrial Internet and intelligent monitoring.

Green energy-saving manufacturing

Optimize heat treatment and wastewater and waste gas treatment processes, reduce resource consumption, and comply with environmental protection policies.

Enhance high-end accessories capabilities

In the face of Inconel series tubes with higher forging difficulty, continue to improve technical solutions such as lubrication, cooling, and annealing.

Improve customer collaboration mechanism

Through joint trial production, technology sharing sessions, etc., achieve solution collaboration in the early stage of product development and reduce the cost of later adjustments.

Starting from the details: Analyzing the workmanship practice in steel tube manufacturing

Definition and Importance of Workmanship

Workmanship, or process quality, refers to the level of strict compliance and execution of details and technical specifications during the manufacturing process of a product. In the steel tube manufacturing industry, good workmanship can ensure the structural integrity and performance of the product. Jiangsu Jend Tube Co., Ltd. strictly controls the process at every step from raw material procurement to finished product delivery to ensure that the product meets the needs of the international market.

Process requirements in raw material selection

The quality of steel tubes is determined from the raw materials. Workmanship requires comprehensive inspection of the chemical composition, purity and physical properties of steel. Jiangsu Jend Tube Co., Ltd. selects high-quality materials that meet standards through perfect supply chain management and a rigorous inspection system, providing a solid foundation for subsequent production.

Process control in the manufacturing process

The manufacture of seamless steel tubes involves multiple processes, such as rolling, forming, welding, heat treatment, etc. Each process requires precise operation to avoid dimensional errors and structural defects. Workmanship is reflected in the technical level of operators and the advanced level of equipment. Jiangsu Jend Tube Co., Ltd. focuses on training employees and adopts automated equipment to improve the stability and consistency of the process.

The relationship between welding process and workmanship

Welding quality is an important factor affecting the performance of steel tubes. The detailed processing of process quality, including the selection of welding materials, temperature control and operating specifications, directly determines the strength and sealing of the weld. Jiangsu Jend Tube Co., Ltd. uses strict welding process standards and multiple testing methods to ensure that the welding part is defect-free and ensure the safe use of the product.

The role of inspection and testing in process quality assurance

Quality inspection is an important link in measuring workmanship. The use of non-destructive testing technologies such as ultrasonic flaw detection, X-ray detection, and magnetic particle detection can timely detect internal defects and surface flaws. Jiangsu Jend Tube Co., Ltd. has established a complete inspection system to ensure that each batch of products meets quality requirements.

Technology research and development and process improvement promote workmanship improvement

Continuous technology research and development and process optimization are important guarantees for maintaining workmanship levels. Jiangsu Jend Tube Co., Ltd. continuously introduces new technologies, improves production processes, and promotes production process upgrades through experiments and practical application feedback, making products more stable and meeting the needs of different customers.

The relationship between employee quality and workmanship

The professional skills and sense of responsibility of employees directly affect the implementation effect of workmanship. The company pays attention to talent training, regularly organizes skill training and quality awareness improvement, and ensures that personnel in each link can accurately implement process standards and reduce human errors.

The impact of workmanship on market competitiveness

Excellent process quality can improve the market recognition and customer satisfaction of products. Jiangsu Jend Tube Co., Ltd. has ensured the reliability of its products through stable workmanship, won the trust of domestic and foreign markets, and laid a solid foundation for the development of the enterprise.

한국어

한국어 русский

русский عربى

عربى