We understand the challenges of various industries, and manufacture reliable quality products through top-notch equipment and professional production technology, so that customers' ideas can be quickly realized.

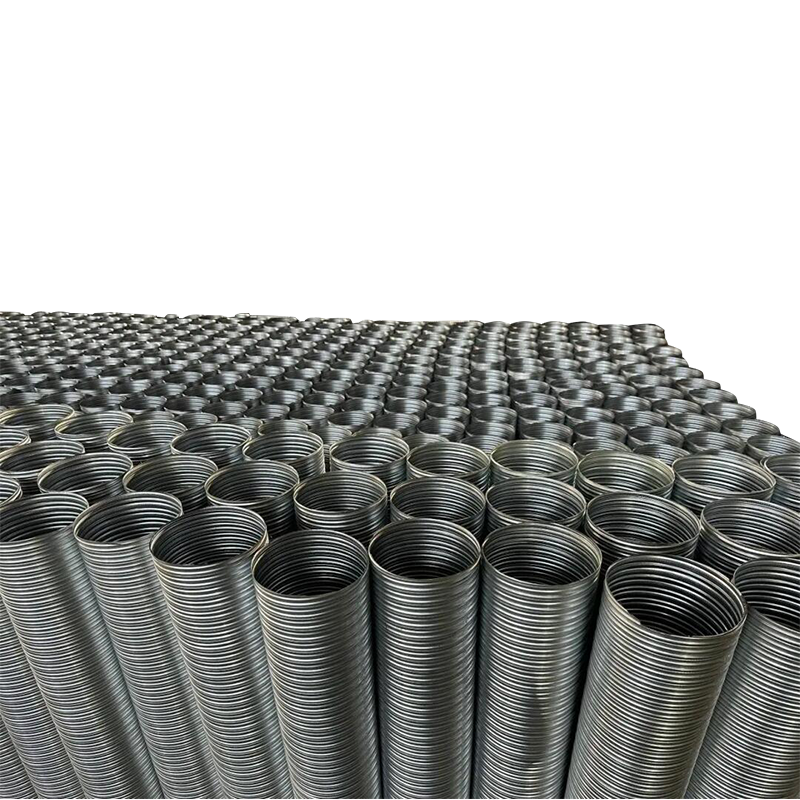

Stainless Steel Coil Tube is a metal coil that has been finely surface treated. It is usually made of stainless steel, copper alloy, aluminum alloy and other materials, and has a highly smooth and glossy surface. The processing of bright coil pipe includes heat treatment, cold processing and electrolytic polishing, which makes its surface smoother and has fewer surface defects, thereby enhancing its corrosion resistance and wear resistance. Compared with conventional coils, bright coil pipes have a more beautiful appearance and a mirror effect on the surface, which can effectively prevent the adhesion of dirt and microorganisms and ensure its long-term stable performance.

Stainless Steel Coil Tubes are widely used in industries that require high cleanliness and corrosion resistance. Especially in the fields of pharmaceuticals, food processing, chemicals, and electronic equipment manufacturing, bright coil pipes have become key components in many precision equipment and production processes due to their excellent hygiene and anti-pollution capabilities. In the pharmaceutical industry, bright coil pipes are often used for the transmission of raw materials and liquids in the production process of drugs, while in the food processing industry, they are used to transport liquids and gases to ensure that the product will not be contaminated during operation and meet strict hygiene standards.

Stainless Steel Coil Tubes are also widely used in heat exchangers, air conditioning systems, condensers and other equipment. In these fields, their smooth surface can improve the flow efficiency of the fluid, reduce energy loss, and improve the heat exchange effect. Its corrosion resistance allows the bright coil pipe to maintain stability in chemical reaction processes and high temperature and high pressure environments, thus extending the service life of the equipment.

한국어

한국어 русский

русский عربى

عربى