We understand the challenges of various industries, and manufacture reliable quality products through top-notch equipment and professional production technology, so that customers' ideas can be quickly realized.

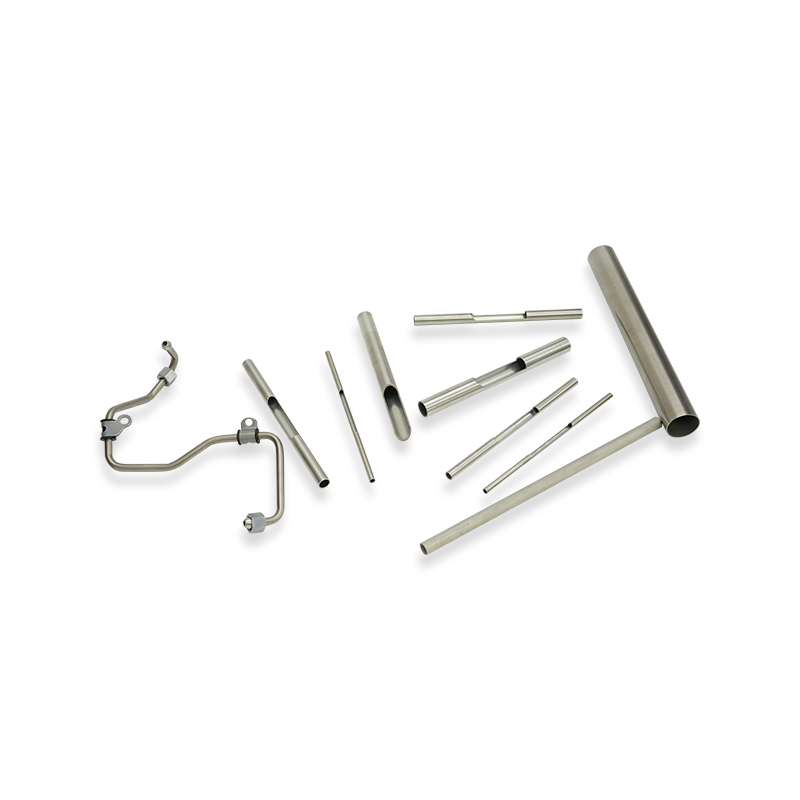

Precision steel pipes for automobiles are high-precision steel pipes for automobiles designed specifically for the automobile manufacturing industry. They are widely used in various key parts of automobiles, such as body, chassis, suspension system, brake system and engine parts. These steel pipes are usually processed by cold drawing, hot rolling and other processes, with precise outer diameter and wall thickness control, which can meet the requirements of the automotive industry for dimensional accuracy, strength and durability. The main characteristics of precision steel pipes for automobiles are good mechanical properties, corrosion resistance and processability, which enable them to be used stably and for a long time in complex automotive working environments.

In the production process of automobiles, precision steel pipes for automobiles are used as important materials for multiple load-bearing components. They can withstand greater pressure and stress and maintain good structural stability under high temperature or high load conditions. The corrosion resistance of precision steel pipes for automobiles also enables them to remain stable for a long time in humid or chemical-rich environments, reducing maintenance requirements.

The processing performance of precision steel pipes for automobiles makes them suitable for processing processes such as welding, bending and cutting to adapt to complex structures and different size requirements. Through heat treatment and other technologies, precision steel pipes for automobiles can further improve their mechanical properties and wear resistance to meet the various working conditions of automobiles in daily use.

한국어

한국어 русский

русский عربى

عربى