We understand the challenges of various industries, and manufacture reliable quality products through top-notch equipment and professional production technology, so that customers' ideas can be quickly realized.

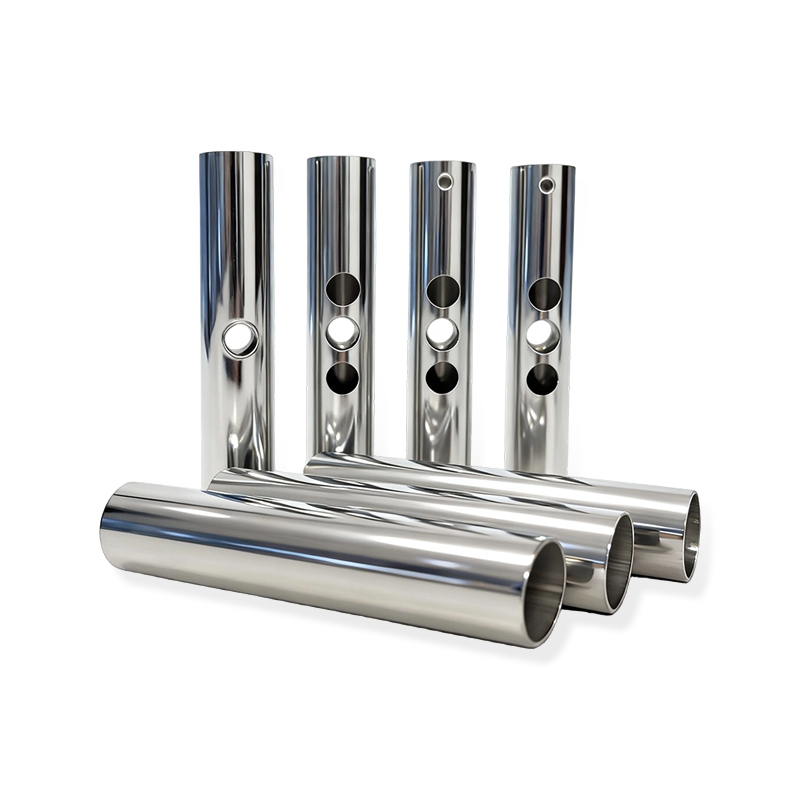

Precision stainless steel air conditioning welded pipe

Specifically designed for HVAC systems: High cleanliness and high precision stainless steel air conditioning welded tubes.

In modern HVAC systems, the quality of each pipe directly impacts the overall system's energy efficiency, stability, and lifespan. As a professional stainless steel pipe manufacturer, we understand this well and have introduced high-quality stainless steel welded pipes specifically designed for air conditioning systems, making them the perfect base material for deep processing such as drilling and bending.

1. Exemplary craftsmanship, defining inner purity

Our air conditioning welding tubes are manufactured using advanced precision cold rolling and cold drawing processes, ensuring exceptional dimensional accuracy and consistent mechanical performance. The core advantage lies in achieving a mirror-like surface finish with an inner wall roughness of Ra≤0.4μm. This level of cleanliness far surpasses that of conventional tubing, effectively reducing refrigerant flow resistance, significantly enhancing heat exchange efficiency, and greatly minimizing the risk of impurity adhesion and oil residue buildup, thereby establishing the first line of defense for long-term clean operation of refrigeration systems.

2. Stable and reliable, empowering efficient processing

We fully understand that the raw materials you procure must undergo subsequent precision processing such as punching and tube expansion. Our steel pipes, with their excellent ductility and uniform wall thickness, ensure resistance to cracking and deformation during secondary processing, delivering superior formability. This not only enhances your production efficiency but also guarantees the structural integrity and reliability of your final products (such as heat exchangers, condensers, etc.).

3. Core Values, Driving System Optimization

Choosing our stainless steel air conditioning welding tubes means selecting for your HVAC core components:

· Higher energy efficiency: The low-flow-resistance inner wall helps reduce energy consumption and improve system efficiency.

· Longer Lifespan: Exceptional corrosion resistance and clean inner walls extend system maintenance intervals.

· Enhanced Protection: Stable material quality and precision ensure the smooth execution of your precision machining processes. We are committed to being your most reliable supply chain partner, using precision-engineered materials to help you build high-performance air conditioning systems. Contact us to obtain detailed technical specifications and samples, and explore potential collaboration opportunities together.

Featured Products

about JEND

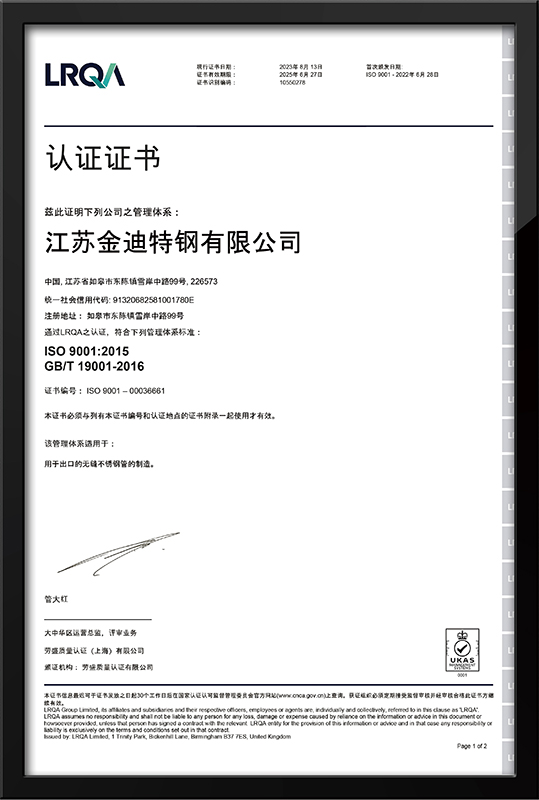

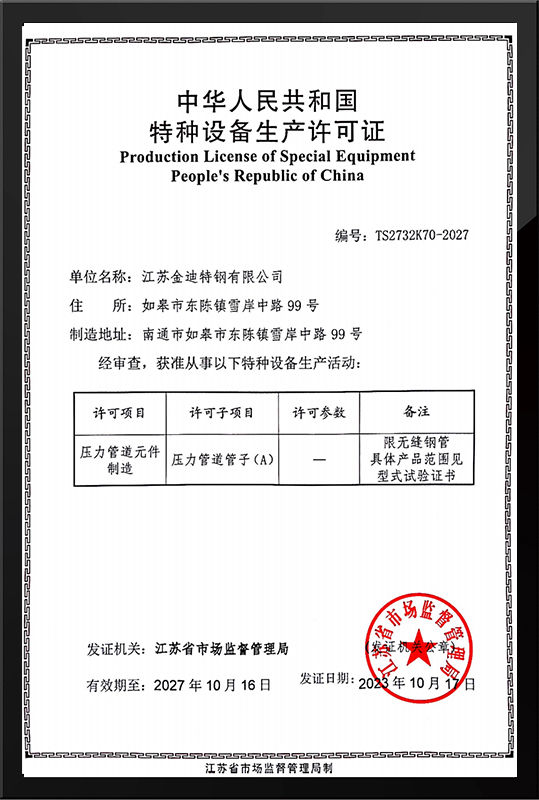

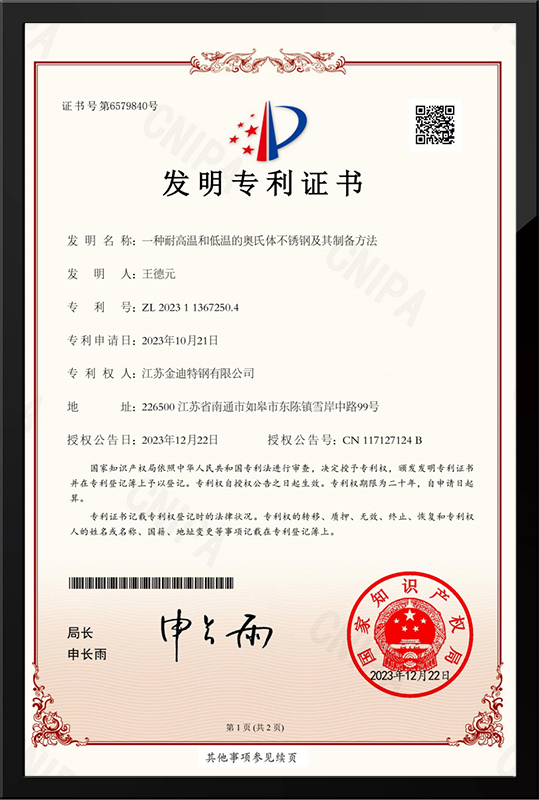

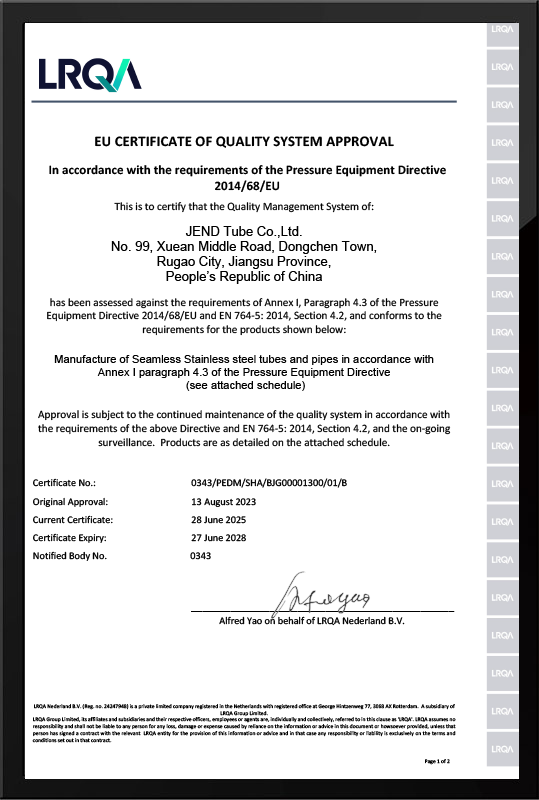

Jiangsu Jend Tube Co.,Ltd. is Precision stainless steel air conditioning welded pipe Manufacturers and Precision stainless steel air conditioning welded pipe Factory, Established in 2011 and is a manufacturing enterprise with a complete manufacturing cycle from raw material selection to finished product delivery. The company currently has more than 100 employees, covers an area of 30015 square meters, and has a registered captial of 48 million yuan, annual production capacity of 3800 tons. The company has passed ISO9001:2015 quality certification, domestic pressure vessel TS certification, and foreign pressure vessel PED certification. With rich experience and mature technology, we have been expanding our market internationally. At present, our products are exported to more than 50 countries and regions including Europe, America, Southeast Asia, and the Middle East. The company adheres to different production norms and standards such as the American standard (ASTM), the European standard (EN), the German standard (DIN), the Japanese standard (JIS), the Russian standard (GOST), and the Chinese standard (GB). Our company specializes in and customizes various specifications of Martensite TP410 (0Cr13, 1Cr13), Ferrite TP405 (1Cr13Al), TP430 (1Cr17), TP444 (0Cr18Mo2), TP439, TP409 (0Cr11Ti), It is also proficient in manufacturing Austenitic seamless stainless steel pipes of series such as TP304(L/H),TP316(L/H/Ti),TP310S,TP317,TP321(H) and TP347(H). Duplex such as S31803、S2205、S32750、S32304, and Nickel-based alloys Monel400, Monel600, Monel800, GH3030, 904L,Inconel 625,etc. The company mainly produces seamless steel pipes with the following specifications: outer diameter: 3.18mm to 406.4mm, wall thickness: 0.3mm to 20mm, and the longest length is 25000mm. Additionally, it can customize seamless steel pipes with special materials and specifications according to customer requirements. The company attaches great importance to scientific innovation. The staff of the company vigorously develop technological research and development. Jiangsu Jend Tube Co.,Ltd.will continuously accumulate professional knowledge and capabilities, striving to become a leader in the domestic market and even the world market. Strive to be the most reassurring pipe manufacturing enterprise for customers.

news

centerAuthentic reliable quality naturally stands out and fears no comparison.

All news-

Why is Austenitic Stainless Steel Tube the Best Choice for High-Corrosion Environments

Unveiling Stainless Steel: From Alloy Definition to the Core of Austenite Stainless steel is not a single material but a vast family of iron-based alloys. The core characteristic is a chromium (Cr) content of at least 10.5%. When chromium reacts with oxygen, it forms an extremely

-

Why is the Austenitic Stainless Steel Tube the Top Choice for Industrial Piping

In the realm of modern industrial manufacturing and fluid transport, the selection of stainless steel tubing directly dictates the safety and longevity of the entire system. The stainless property of this steel is primarily derived from a chromium content of no less than 10.5 per

-

Which Stainless Steel Tube Type is Best for Your Project? (304 vs 316 vs 2205)

Austenitic Stainless Steel Tubing Austenitic stainless steel tubing is the most widely used category of Stainless Steel Tube in both industrial and civil fields. Its microstructure features a face-centered cubic lattice, which allows it to maintain excellent toughness and ductili

한국어

한국어 русский

русский عربى

عربى