We understand the challenges of various industries, and manufacture reliable quality products through top-notch equipment and professional production technology, so that customers' ideas can be quickly realized.

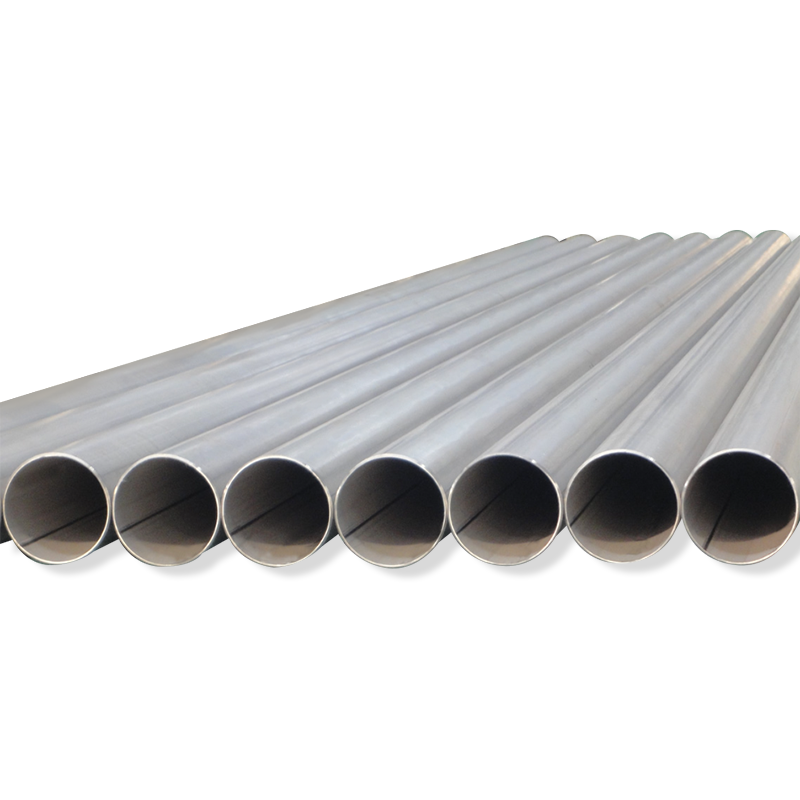

Welded Tube is a pipe made by welding metal sheets or strips, which is widely used in various industries. The production process of welded pipe usually includes steps such as coiling, welding, cooling and sizing. The main welding methods used are high-frequency welding, submerged arc welding, gas shielded welding, etc. The main feature of welded pipe is that metal materials are connected by welding process to form a tubular structure, which has high production efficiency and low manufacturing cost. The size and wall thickness of welded pipe can be customized according to needs and are suitable for different applications.

The material types of welded pipe are relatively rich, including carbon steel, stainless steel, alloy steel, etc., which can meet the needs of different working environments. Welded pipe has a wide range of applications in the transportation of liquids, gases, oil products, etc., and plays an important role in construction, chemical industry, petroleum, natural gas, electric power and other industries. They are often used in water pipes, gas pipes, cable protection pipes, structural pipes, etc., to play a supporting and protective role.

Compared with seamless pipes, the production process of welded pipes is relatively simple and the cost is low. Therefore, welded pipes have become an economical and practical choice in many occasions. The advantages of welded pipes are particularly obvious when large-scale production is required. In addition, the surface treatment processes of welded pipes are diverse, including painting, galvanizing, coating, etc., which can provide additional protection according to different usage environments and extend the service life of the pipeline.

한국어

한국어 русский

русский عربى

عربى